Why the Best Building Envelopes Are Designed as Systems

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

Installing electrical systems in a structure built with structural insulated panels (SIPs) is different than with traditional framing—but different doesn't mean difficult. In fact, with a little up-front planning, SIPs make electrical installation more streamlined, thanks to integrated chases that eliminate the need for hours of drilling and routing.

Here’s what to know before you start pulling wire.

Unlike stick framing, SIPs come with electrical chases pre-installed during manufacturing. These chases—horizontal and vertical channels inside the rigid foam core—allow for easy routing of electrical wiring. Because these can’t be added once the panels are installed, a detailed electrical plan is essential before fabrication begins.

What should be decided early?

The electrical plan should be shared with both the SIP manufacturer and the contractor to ensure all required chases are in the right locations. Need help building out your plan? Our electrical planning guide has example drawings and tools to get you started.

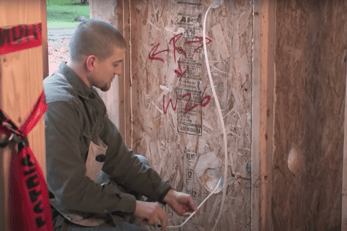

Once the panels arrive on site, installation is straightforward. SIPs are clearly marked to indicate where the electrical chases run. Electricians can easily locate and cut into the oriented strand board (OSB) skin at any point along the chase line to place outlet or switch boxes.

Wiring can be pulled or pushed through the chases using a fish tape or hook. This dramatically reduces the time spent drilling holes through dozens of studs and helps maintain the airtight envelope that makes SIPs so energy efficient.

Watch this step-by-step demo of electrical installation with Premier SIPs.

While it's possible to add a new chase after the panels are installed, it’s far more time-consuming and should only be a last resort. Cutting through the foam and ensuring the structural integrity of the panel is maintained requires careful attention. That’s why working closely with your SIP manufacturer from the beginning is so important.

Need to explain the process to your trades? Share this quick video overview with your subcontractors.

For the most accurate installation and chase-creation instructions, consult the Manufacturer’s Installation Guide.

Good communication and planning are the key to a smooth electrical install with SIPs. By front-loading the design process, you’ll minimize surprises onsite and keep your build efficient, fast, and clean. The result? Less labor, fewer delays, and a high-performance structure that stays sealed and efficient.

For more tips, resources, and sample layouts, visit our Premier SIPS Electrical Page or reach out to your local rep for design assistance.

Want to see it in action?

Several electrical solutions are demonstrated in video below from the Structural Insulated Panel Association.

See how to run wires from:

More info on SIPS & Electrical:

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

Lumber tariffs driving up costs? SIPs cut lumber use by up to 80%, lower labor needs, and deliver stronger, faster, more..

Learn what’s changing—and what’s not—with energy tax credits for SIP projects. Get the latest updates on 25D, 45L, 179D, and..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.