How Airtightness Drives Energy, Comfort, and Durability in Buildings

Airtightness isn’t about test scores. Learn how integrated envelope design improves energy efficiency, comfort, moisture..

When it comes to choosing building materials, the decision between engineered wood and dimensional lumber has a significant impact on quality, budget, and longevity. With increasing attention on engineered wood products like LVL, OSB, and I-joists, it’s important for builders to understand how these manufactured wood solutions compare to traditional dimension lumber.

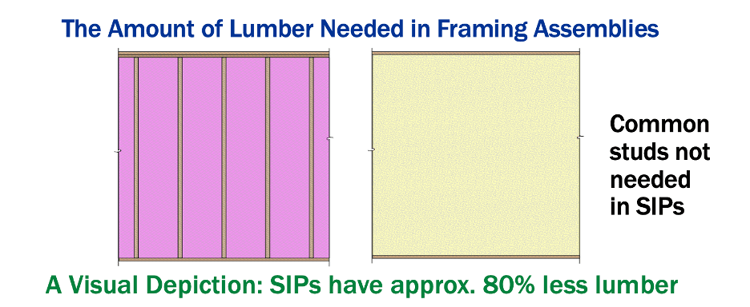

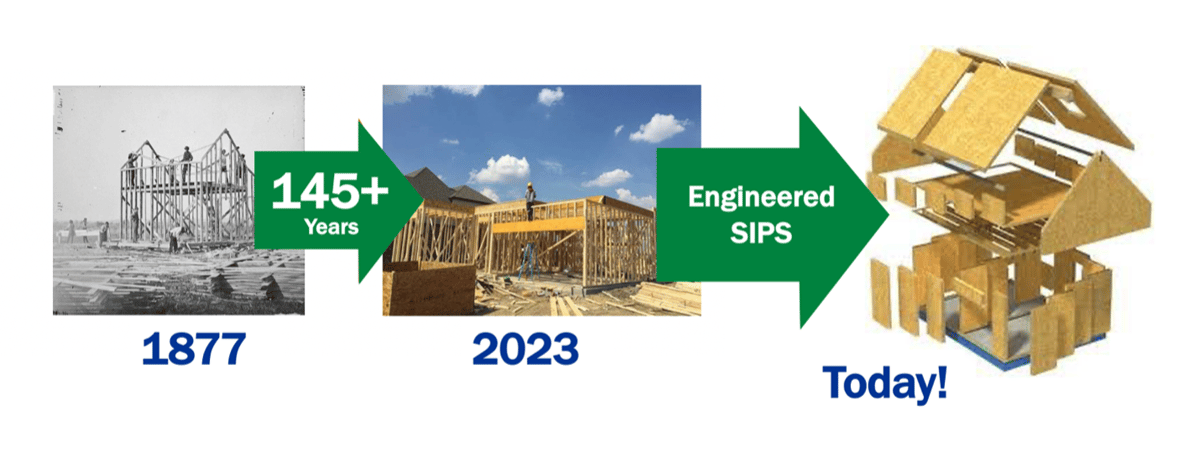

At Premier SIPS, we help builders maximize the benefits of both engineered construction products and offsite manufacturing. Our Structural Insulated Panels (SIPs) use engineered wood material for the OSB skins and engineered lumber components like headers and beams—while eliminating the need for 80% of the dimensional lumber found in typical stick-framed buildings.

Engineered wood components, such as laminated veneer lumber (LVL) and structural grade-oriented strand board (OSB) used in SIPs, offers numerous advantages over traditional dimensional lumber. Read on to explore the key benefits of engineered wood and how they translate into advantages for builders, including improved quality, enhanced precision, faster installation, reduced waste, and often structural warranties.

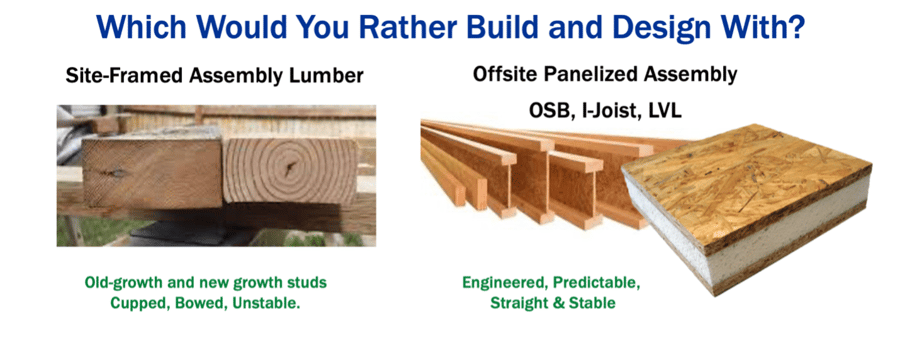

One of the top advantages of engineered wood is consistency. Unlike dimensional lumber, which may contain knots, warping, or moisture variability, engineered studs and sheathing are produced to exact specifications. That means fewer on-site corrections, straighter walls, and better alignment throughout construction.

What is engineered wood? It’s a processed wood product made from layers of wood bonded with adhesives to create reliable, high-performance fabricated wood components.

Engineered wood lumber is stronger and more stable than traditional timber framing. Whether it’s LVL beams, I-joists, or OSB sheathing, these engineered construction products offer superior strength-to-weight ratios and can be manufactured in larger sizes. SIPs, for example, come in sizes up to 8’x24’, allowing full wall sections to be installed in minutes. That’s something no stack of 2x6 dimensional framing lumber can do.

Wondering what lumber is more flexible? Engineered wood tends to outperform dimensional lumber in both strength and load-bearing flexibility—especially across longer spans.

Premier SIPS roof, wall, and floor panels are backed by a 20-year structural and 50-year thermal warranty. You won’t find that with standard dimensional lumber. These engineered lumber products are designed to last—without the callbacks and concerns of settling or cracking over time.

Engineered wood's dimensional stability ensures straight and plumb buildings, reducing the need for on-site adjustments. This not only saves time but also improves the overall aesthetics and functionality of the structure. Builders can achieve precise alignments and eliminate the frustrations associated with working with natural timber's inherent inconsistencies.

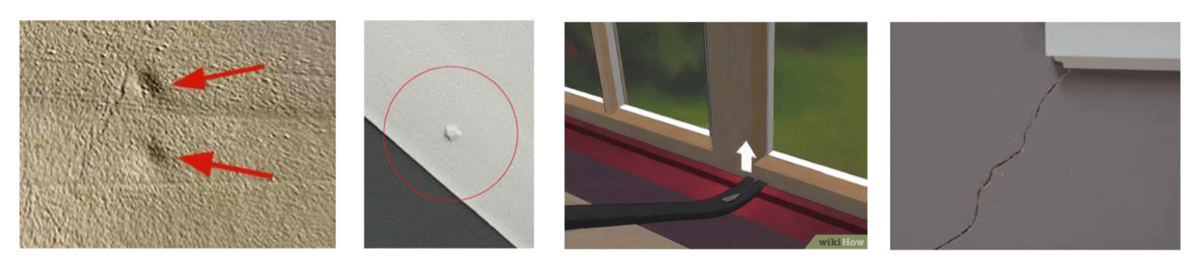

The precision, strength, and predictability of engineered wood contribute to the production of a superior end product. By using engineered wood, builders can create structures with tighter tolerances, minimizing issues such as warping, twisting, or settling. The result is a building that not only looks better but also performs better over time.

SIPs eliminate the guesswork of lumber construction by using pre-cut, pre-labeled panels made with engineered lumber. This speeds up framing time by up to 55% and minimizes errors. Builders working with engineered studs and panels also report straighter, cleaner installs—and happier clients.

View time lapse videos “SIPs in Action” of engineered SIP installations which are proven to regularly cut framing time by 55%.

Warped dimentional lumber can lead to uneven surfaces, shifting door frames, or cracked drywall. Premier’s SIP assemblies—made with engineered wood—help builders avoid those pitfalls. Tested to be 55% stronger than a 2x6 stick-framed wall, SIPs are approved in seismic zones, coastal conditions, and high-wind regions like Miami-Dade County.

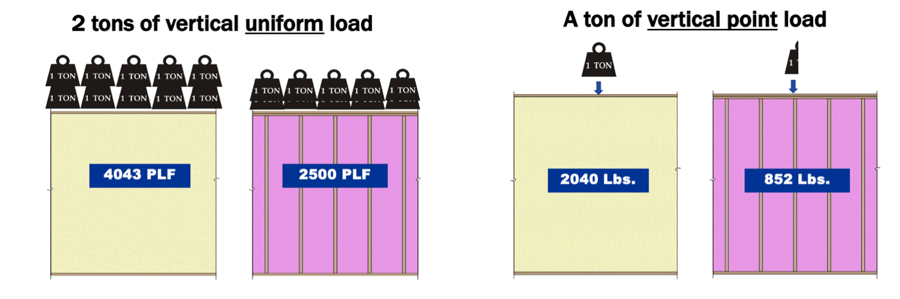

Engineered wood products also test much stronger than dimensional lumber. In fact, engineered SIPs roof and wall panels are tested and verified 55% stronger than a typical 2x6” stick framed lumber assembly. This is due in part to the engineered structural OSB facings, as well as the moisture cured structural adhesive used in the lamination process of each panel. Premier’s Structural Insulated Panel assemblies are so strong they are approved in all seismic zones, approved in coastal regions and the Structural Insulated Panel Association documents how SIPs are hurricane approved in challenging counties like Miami Dade, FL. Watch this video to see how the structural engineered OSB, when laminated in a SIP assembly, delivers exceptional strength.

Engineered wood products also test much stronger than dimensional lumber. In fact, engineered SIPs roof and wall panels are tested and verified 55% stronger than a typical 2x6” stick framed lumber assembly. This is due in part to the engineered structural OSB facings, as well as the moisture cured structural adhesive used in the lamination process of each panel. Premier’s Structural Insulated Panel assemblies are so strong they are approved in all seismic zones, approved in coastal regions and the Structural Insulated Panel Association documents how SIPs are hurricane approved in challenging counties like Miami Dade, FL. Watch this video to see how the structural engineered OSB, when laminated in a SIP assembly, delivers exceptional strength.

The NAHB reports that an average job site generates over 8,000 lbs of waste—much of it manufactured lumber and framing scrap. With SIPs, there’s far less cutting, less landfill waste, and lower disposal fees. Builders report up to 30% cost savings in waste management alone.

Bonus: Reduced lumber waste = less environmental impact. Learn how engineered wood helps builders align with sustainability goals.

Choosing between engineered wood vs dimensional lumber is no longer just a budget decision—it’s about long-term performance, speed, and sustainability. Builders using SIPs and engineered framing lumber experience faster builds, fewer problems, and higher client satisfaction.

Explore how Premier SIPS, made with engineered wood meaningfully optimized for strength, can deliver superior results for your next project.

Engineered wood presents a host of advantages over dimensional lumber, making it an ideal choice for builders. From precision and predictability to increased strength and size, engineered wood offers improved quality, faster installation, reduced waste, and often structural warranties. By embracing the benefits of engineered wood, builders can elevate the quality and strength of homes and buildings created, while making a positive impact on the environment.

Airtightness isn’t about test scores. Learn how integrated envelope design improves energy efficiency, comfort, moisture..

Labor conditions vary from job to job. Learn how systems-based design supports consistent building performance despite..

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.