Why Every Building Must Manage Moisture, Regardless of Climate

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

In the world of construction, time is money, and the innovative realm of Structural Insulated Panels (SIPS) is transforming the industry by revolutionizing the speed of building projects. From expediting the drying process to minimizing loan costs, SIPS construction is a game-changer in numerous ways. In this article, we'll delve into how SIPS technology is propelling construction forward at a remarkable pace and explore the offsite construction systems' far-reaching implications.

Drying In Faster: Weather Woes and Site Challenges No More Traditional site framed construction methods often leave buildings vulnerable to the elements for extended periods. But with SIPS, this narrative changes dramatically. Thanks to the insulated panels' energy efficiency and weather-resistant qualities, SIPS buildings are dried in at an accelerated rate. This means less susceptibility to weather-related damages and the ability to advance to subsequent construction phases swiftly. Rain, snow, or shine, SIPS construction ensures that progress remains uninterrupted. From hot desert climates to the snow and ice in the arctic designers and owners are turning to structural insulated panels on a regular basis.

Traditional site framed construction methods often leave buildings vulnerable to the elements for extended periods. But with SIPS, this narrative changes dramatically. Thanks to the insulated panels' energy efficiency and weather-resistant qualities, SIPS buildings are dried in at an accelerated rate. This means less susceptibility to weather-related damages and the ability to advance to subsequent construction phases swiftly. Rain, snow, or shine, SIPS construction ensures that progress remains uninterrupted. From hot desert climates to the snow and ice in the arctic designers and owners are turning to structural insulated panels on a regular basis.

Precise Prefabrication for Swift Assembly

The secret to the rapid installation offered by SIPS lies in the panels themselves. These panels are meticulously prefabricated off-site, precisely tailored to the project's floor plans. Large panels can be produced in sizes up to 24' x 8' in size. The elimination of on-site measuring, cutting, and adjustments eliminates the time-consuming variables (and errors) that often delay conventional construction. When the panels arrive at the site, they are ready to be tilted into place, like fitting the pieces of a well-designed puzzle. This meticulous prefabrication streamlines the assembly process, enabling construction teams to progress quickly to subsequent phases.

A Symphony of Structure, Sheathing, and Insulation in One Piece

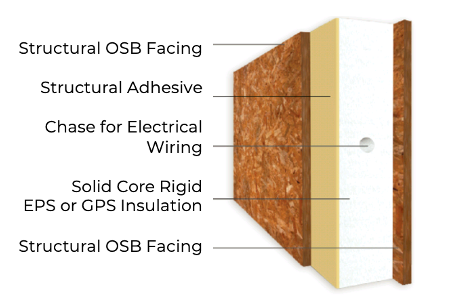

One of the key attributes of SIPS panels is their comprehensive design. Each panel is not just a piece of sheathing or insulation; it's an all-in-one powerhouse that combines structural integrity, sheathing, and insulation into a single unit. This holistic approach eliminates the need for multiple steps in the construction process. Traditional methods often involve separate steps for framing, sheathing, and insulation, each requiring its set of time-consuming tasks and different contractors each with their own schedule. With SIPS, it's a one-and-done scenario, with the structural and insulated panels seamlessly providing all the required elements in a single placement.

One of the key attributes of SIPS panels is their comprehensive design. Each panel is not just a piece of sheathing or insulation; it's an all-in-one powerhouse that combines structural integrity, sheathing, and insulation into a single unit. This holistic approach eliminates the need for multiple steps in the construction process. Traditional methods often involve separate steps for framing, sheathing, and insulation, each requiring its set of time-consuming tasks and different contractors each with their own schedule. With SIPS, it's a one-and-done scenario, with the structural and insulated panels seamlessly providing all the required elements in a single placement.

As a testament to the speed that SIP construction delivers is a 60-unit apartment building in Tioga, North Dakota that was 100% complete and ready for occupancy in 89 days. The Contractor attributes the speed of construction almost entirely to choosing to convert the project to Premier SIPS.

Speed Sparks a Chain Reaction: Enabling Earlier Trades and Reducing Costs

SIPS construction sets a new rhythm for the entire construction process. As buildings are dried in rapidly, other trades can start their work earlier than with traditional site framing methods. This synchronized workflow results in an overall reduction of project timelines, translating into cost savings. Reduced construction loan costs and decreased interest expenses occur when buildings are occupied faster, optimizing resource allocation and minimizing financial burdens.

Battling Skilled Labor Shortages: SIPS to the Rescue

The construction industry has long been grappling with a shortage of skilled labor.The issue is widespread: 92% of contractors have reported difficulty finding construction workers and of those, 42% said they have turned down work because of it, according to the U.S. Chamber of Commerce Commercial Construction Index.

This shortage has implications for project timelines and costs. However, SIPS technology emerges as a beacon of hope in these challenging times. A study conducted by the Associated Builders and Contractors, sheds light on the labor crisis contractors face. The construction industry’s outlook for labor is bleak. In the study the ABC says in order to meet demand, contractors will need to hire an estimated 546,000 workers in 2023 alone, and that’s in addition to the industry’s normal pace of hiring.

This shortage has implications for project timelines and costs. However, SIPS technology emerges as a beacon of hope in these challenging times. A study conducted by the Associated Builders and Contractors, sheds light on the labor crisis contractors face. The construction industry’s outlook for labor is bleak. In the study the ABC says in order to meet demand, contractors will need to hire an estimated 546,000 workers in 2023 alone, and that’s in addition to the industry’s normal pace of hiring.

The challenge within the construction industry's high demand doesn't solely stem from the scarcity of labor; it's also compounded by a shortage of skilled workers, said Anirban Basu, ABC’s chief economist. The struggle to hire and retain workers is especially dire, as the workforce increasingly reaches retirement age. Few younger workers join the workforce, and when they do, they are less experienced and therefore less efficient.

Skilled labor shortages seem to be a persistent issue with no immediate resolution in sight. Here, SIPS technology comes to the forefront, offering a solution that doesn't rely heavily on a vast pool of skilled labor.

RS Means Study: A Resounding Validation of SIPS Speed A study conducted by RS Means, the industry standard for labor study research, underscores the transformative impact of SIPS on construction speed. The study evaluated two comparable homes, one constructed using conventional stick framing and the other utilizing SIPS technology. Both homes were 2500 square feet in size. The results were staggering - the SIPS building reduced installation time by a whopping 130 labor hours, a 55% faster rate compared to conventional framing. The study's findings validate the tangible advantages of SIPS in the context of speed and efficiency. View the full study here.

A study conducted by RS Means, the industry standard for labor study research, underscores the transformative impact of SIPS on construction speed. The study evaluated two comparable homes, one constructed using conventional stick framing and the other utilizing SIPS technology. Both homes were 2500 square feet in size. The results were staggering - the SIPS building reduced installation time by a whopping 130 labor hours, a 55% faster rate compared to conventional framing. The study's findings validate the tangible advantages of SIPS in the context of speed and efficiency. View the full study here.

Speed Amplified by Energy Efficiency and Weather Resistance

The efficiency of SIP panels construction extends beyond their prefabricated nature. Thanks to the panels' energy efficiency and exceptional weather-resistant qualities, SIPS buildings experience an accelerated drying process. The panels' insulation properties create a well-insulated environment that resists external temperature fluctuations, contributing to faster drying times (and significantly lower operating costs for building owners). This not only expedites subsequent construction phases but also minimizes potential weather-related damages.

The efficiency of SIP panels construction extends beyond their prefabricated nature. Thanks to the panels' energy efficiency and exceptional weather-resistant qualities, SIPS buildings experience an accelerated drying process. The panels' insulation properties create a well-insulated environment that resists external temperature fluctuations, contributing to faster drying times (and significantly lower operating costs for building owners). This not only expedites subsequent construction phases but also minimizes potential weather-related damages.

In the realm of construction, time is undeniably a valuable currency. With SIPS technology, the currency of time gains newfound strength as the assembly process is accelerated by prefabrication, precision, and the elimination of traditional complexities. From mitigating weather challenges and tough site conditions to combatting skilled labor shortages, SIPS offsite construction systems presents a solution that addresses numerous industry pain points. The RS Means study serves as a testament to the remarkable speed gains offered by SIPS construction. As construction industries grapple with skilled labor shortages, challenging weather conditions, and the pursuit of enhanced efficiency, SIPS emerges as a beacon of innovation, charting a faster, more efficient course for the future of construction.

Weather limited the install window, and freezing temps demanded strength for snow loads

with operational energy efficiency for long term savings and ecological advantages.

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

A field perspective on SIP construction details, best practices, and common questions—from panel connections to electrical..

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.