Why Every Building Must Manage Moisture, Regardless of Climate

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

In our last installment, we talked about the key elements of what high-performance building envelopes (HPBE) must possess. Revisit that Tech Talk here.

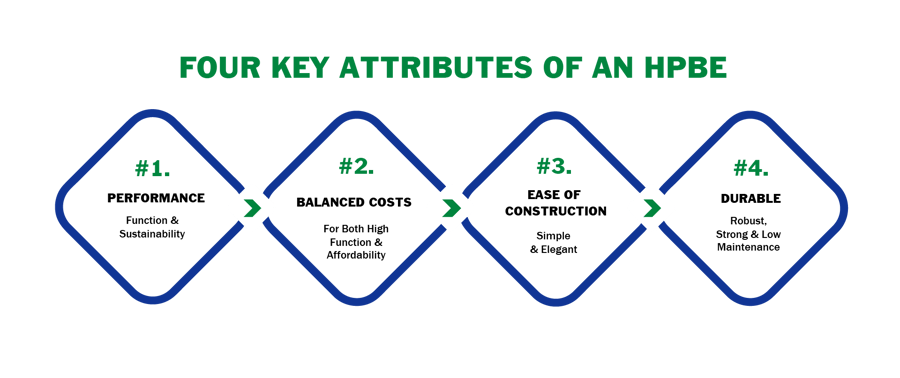

In review, an HPBE must:

To achieve these goals, an HPBE needs to be made with building envelope materials that, when assembled, act as a functioning building envelope system. Let’s consider what building envelope components could be made of. We’ll first look at various building assemblies widely used to construct a wall envelope.

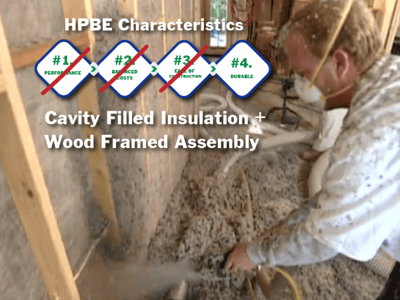

Wood and metal stud framing, with mineral fiber or spray foam cavity fill and additional continuous rigid insulation, are commonly used to build insulated wall envelopes. While this appears to be a high-performing option, it struggles to fully meet criteria #1–3. The complexity of these assemblies often results in compromised performance if not installed perfectly. Additionally, rising costs of wood and metal make these building envelope systems more expensive and less sustainable.

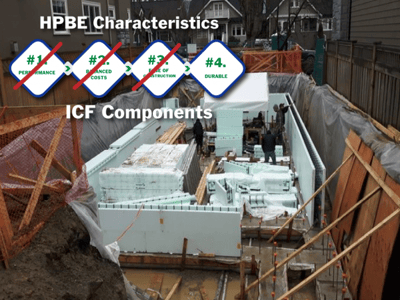

A second example would be Insulating Concrete Forms (ICFs). They are extremely strong, durable, and provide low maintenance and good insulating qualities, but have high material costs, are more difficult to construct as an infield build, and use concrete. They currently have limited acceptance in the marketplace. Therefore, ICFs do not score well in meeting the key elements of #’s 1, 2, and 3 as noted above. To explore this further, read this article, “Why Building with Concrete is Not Sustainable.”

A second example would be Insulating Concrete Forms (ICFs). They are extremely strong, durable, and provide low maintenance and good insulating qualities, but have high material costs, are more difficult to construct as an infield build, and use concrete. They currently have limited acceptance in the marketplace. Therefore, ICFs do not score well in meeting the key elements of #’s 1, 2, and 3 as noted above. To explore this further, read this article, “Why Building with Concrete is Not Sustainable.”

Metal-faced, factory-fabricated façade panels with various core building envelope materials—including EPS, Polyurethane, Polyisocyanurate, and Rock Wool—have become increasingly popular in the commercial building community. These factory-produced building assemblies are attractive, offer high insulating value, and are highly constructible from an installation standpoint.

However, they come with key limitations.

Most notably, these building envelope systems are primarily limited to use as exterior cladding because they lack axial load capabilities. That means they cannot support floor-to-floor or roof-to-wall loads and must be attached to an underlying steel structure that provides the building’s structural support.

Due to this limitation, they are typically used on multi-story buildings in dense urban settings or in climate-controlled industrial facilities, where their insulating performance and sleek appearance are prioritized, but always in conjunction with a secondary load-bearing system.

Because of the need for additional structural support, these building envelope components are expensive. Their high cost and limited use case make them less practical for broader adoption across the mid-rise and low-rise construction market. As a result, they do not score well in key areas like affordability and simplicity of construction—elements 2 and 3 of a truly high-performing building envelope.

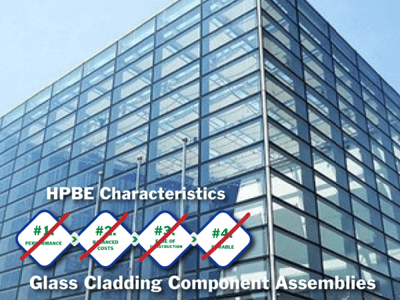

Many urban skylines are dominated by gleaming towers with full glass wall envelope systems. These high-rise structures use metal-framed assemblies clad in architectural glass to create sleek, modern exteriors.

Visually striking? Absolutely. But when it comes to performance, these building envelope systems fall short.

Glass-clad façades have limited structural capacity and require a separate structural frame—typically steel or reinforced concrete—to support building loads. On their own, glass assemblies cannot bear significant weight or axial loads. This makes them more complicated and labor-intensive to install.

They also tend to underperform in terms of energy efficiency. Despite advances in glazing technologies, large-scale glass building envelope examples still result in higher thermal transfer, poor insulation values, and more significant HVAC demands.

Due to these factors—high cost, low energy performance, and installation complexity—glass façade systems are mainly reserved for multi-story commercial buildings in dense urban environments. In fact, they represent only a small percentage of all building assemblies constructed in the U.S. each year.

Ultimately, they fall short across the board in terms of sustainability, affordability, and practicality—meaning they do not meet any of the four key requirements of a true high-performance building envelope.

As noted, traditional building envelope components often fall short in one or more critical areas—sustainability, cost, constructability, or maintenance. These systems are frequently used for insulation in skyscrapers and specialized buildings, not for the vast majority of U.S. structures, which are mid to low-rise.

So what’s the ideal building envelope system?

Structural Insulated Panels (SIPs) check every box.

SIPs are engineered composite panels that combine structure, insulation, and air control into one high-performance solution. They arrive pre-cut and pre-engineered, simplifying installation and reducing errors.

As a complete building envelope assembly, SIPs deliver:

Excellent airtightness and thermal performance

Sustainable materials: OSB (from fast-growing trees) and MPS/GPS insulation

Low GWP and no ozone-depleting blowing agents

Moisture resistance and long-term durability

Fully recyclable core materials

Unlike many building envelope materials that require complex multi-layer assemblies, SIPs are a streamlined solution suitable for nearly every climate and region, especially for commercial and residential building assemblies in mid- and low-rise applications.

Finally, SIPs can be the “every man’s” building system for mid to low-rise commercial and residential buildings based on National Building Code definitions for buildings constructed in all regions of the US.

In our next “Tech Talk” installment we will talk about the specific performance qualities of SIPs as the perfect HPBE to build mid to low-rise commercial and residential buildings. In addition, we will include the use of SIP roof/ceiling assemblies as part of our HPBE advanced master discussions.

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

A field perspective on SIP construction details, best practices, and common questions—from panel connections to electrical..

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.