Designing with Structural Insulated Panels (SIPs) gives architects a powerful tool to create resilient, innovative, and efficient buildings—without adding cost. With superior energy performance, structural strength, and design flexibility, SIPs provide a streamlined, high-performance building envelope that integrates structure, insulation, and airtightness in one system.

By incorporating SIPs from the start, architects can maximize material efficiency, reduce labor, and accelerate construction timelines.  Here’s what you need to know about designing with SIPs and how to optimize your plans for seamless integration. Visit our online Design Resource Library for more helpful information on designing structures with Premier SIPS systems and products.

Here’s what you need to know about designing with SIPs and how to optimize your plans for seamless integration. Visit our online Design Resource Library for more helpful information on designing structures with Premier SIPS systems and products.

⇒ Project Highlight, Colorado Modern Industrial Residence: "We worked very closely with our structural engineer. Premier SIPS are not the traditional nail it or screw it together type of construction. Engineers were able to complement the design with some significant structural/architectural steel frames. The steel structural frames contrast the simplicity of the panel system. It creates an interesting relationship of parts. The results were rewarding. We learned that SIPS are best used as a system to drive the entire project. We look forward to using them again." -Project Architect

Maximizing Construction Efficiency with SIPs

Integrating SIPs into your design requires a strategic approach to panel sizing, structural optimization, and efficient system integration. By following proven design guidelines, architects can enhance material efficiency, reduce waste, and simplify installation.

Panel Optimization & Layout Considerations

- SIPs can be fabricated in sizes up to 8x24 feet, reducing seams, connection points, and installation time.

- Aligning key structural elements, such as windows, doors, and wall placements, with SIP panel dimensions can further enhance efficiency, reducing modifications and material waste.

- Designing in 4-foot increments optimizes material use and minimizes excess cuts, although not required.

- Plate height optimization reduces waste—an 11-foot plate requires a 12-foot panel, increasing material costs unnecessarily. Additionally, designing with standard SIP panel heights (such as 8, 9, or 10 feet) prevents unnecessary trimming, ensuring efficient use of materials and maintaining structural integrity.

Structural Integration for Strength & Flexibility

- SIPs’ high load-bearing capacity eliminates the need for traditional trusses, allowing for vaulted ceilings, open-concept layouts, and conditioned attic spaces. By replacing conventional stick-framed trusses, SIPs enable cleaner, more expansive interior volumes, allowing architects to integrate open-plan concepts, flexible layouts, and high-performance, conditioned attic storage.

- Longer SIP wall spans require fewer connections and splines, reducing labor while maintaining superior structural performance. This efficiency is particularly advantageous for large-scale commercial, educational, and industrial projects where reducing connection points simplifies assembly and enhances durability.

- SIPs provide greater structural strength than traditional stick framing, with OSB skins offering superior load-bearing capacity compared to dimensional lumber. This added strength allows for longer, uninterrupted spans with fewer framing components, creating more design flexibility while maintaining structural integrity.

- Meeting and exceeding shear and seismic requirements, SIPs provide enhanced stability in high-wind and earthquake-prone regions where traditional framing may struggle to comply with modern building codes. Their engineered design ensures resilience, making them an ideal choice for disaster-resistant construction.

HVAC, Plumbing & Electrical Considerations

- Ductwork should be routed within conditioned spaces, with drop ceilings in closets, hallways, and bathrooms for ease of access. Architects can incorporate soffits and bulkheads into the design to seamlessly house mechanical systems while maintaining aesthetic appeal and efficient airflow.

- Plumbing should be placed in interior partition walls, as SIP exterior walls are not designed for water line routing. For designs requiring plumbing near exterior walls, adding interior furring walls can accommodate water lines while maintaining SIP integrity.

- Electrical chases are pre-installed in SIPs, eliminating time-consuming drilling and preserving structural integrity. Specifying panel layouts with strategic chase locations ensures easy electrical access while maintaining the airtight envelope critical for energy performance. For more information, visit our How To: Electrical & SIPS resource page.

Explore our Premier SIPS Technical Bulletins for detailed guidance and expert recommendations on design-specific considerations and best practices.

Design Advantages of SIPs

With efficient material integration, reduced labor demands, and enhanced building performance, SIPs provide unparalleled design flexibility while optimizing project timelines and costs.

Cathedral Ceilings & Open Spaces

- SIPs eliminate the need for trusses, allowing for tall ceilings without additional framing.

- Continuous insulation ensures thermal stability, reduced energy costs, and enhanced indoor comfort.

Long Overhangs & Cantilevers

- SIPs support cantilevers up to 12 feet, expanding design possibilities without requiring additional structural reinforcements.

Custom Wall Thickness & Architectural Features

- Wall thickness does not significantly impact cost, giving designers the freedom to create recessed windows, deeper openings, and enhanced architectural details.

- SIPs enable corner window designs without steel headers or back-spans, simplifying structural requirements. This feature allows for unobstructed views and modern, minimalist aesthetics, making SIPs a preferred choice for contemporary and high-performance architecture.

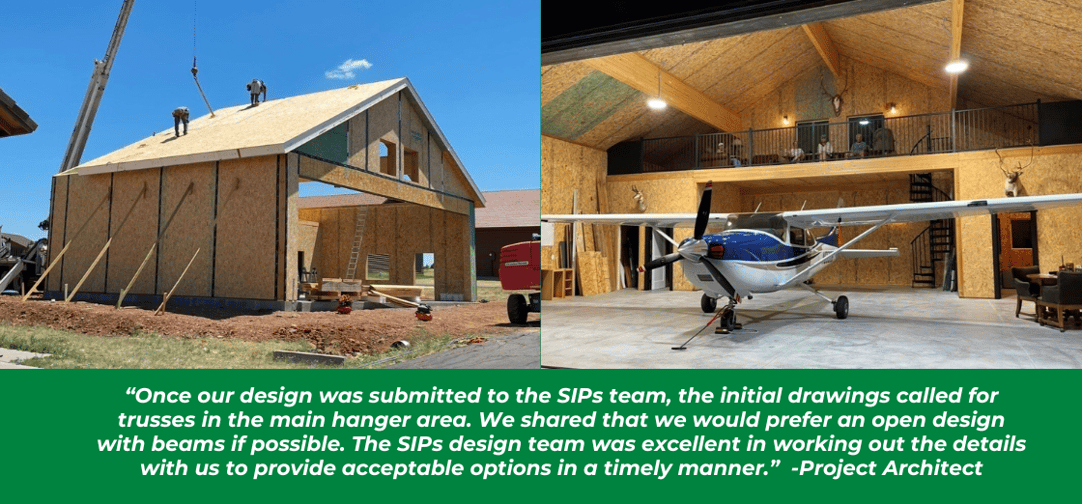

Project Highlight: Arizona Airplane Hanger

SIPs: The Most Efficient Offsite Building Envelope

By integrating SIPs into the design phase, architects can optimize project efficiency while exceeding industry standards for performance, resilience, and sustainability.

- Optimized Energy Efficiency: SIPs exceed code requirements for air infiltration, continuous insulation, and R-values, supporting LEED, Passive House, and NetZero construction.

- Superior Structural Performance: Premier SIPs have the highest seismic testing in all zones, as well as extensive hurricane and high-wind resilience testing, making them ideal for disaster-resistant buildings.

- Accelerated Construction Timelines: SIPs install up to 55% faster than traditional framing, reducing labor costs and allowing for earlier project completion.

Integrate SIPs Into Your Next Design

Design is only as efficient as the building materials used to bring it to life. With SIPs, architects can create structures that are smarter, stronger, and more sustainable—without compromising creativity.

Premier SIPS provides extensive design resources, technical support, and continuing education opportunities to help architects seamlessly integrate SIPs into their projects.

Explore the advantages of SIPs firsthand. Contact your local Premier Rep today to optimize your next design with SIPs.

Additional Key Resources:

Here’s what you need to know about designing with SIPs and how to optimize your plans for seamless integration. Visit our online Design Resource Library for more helpful information on designing structures with Premier SIPS systems and products.

Here’s what you need to know about designing with SIPs and how to optimize your plans for seamless integration. Visit our online Design Resource Library for more helpful information on designing structures with Premier SIPS systems and products.