SIPS vs ZIP: How Airtightness Drives Energy, Comfort, and Durability in Buildings

Comparing two key assemblies designed to combat airtightness. Learn how integrated envelope design improves energy..

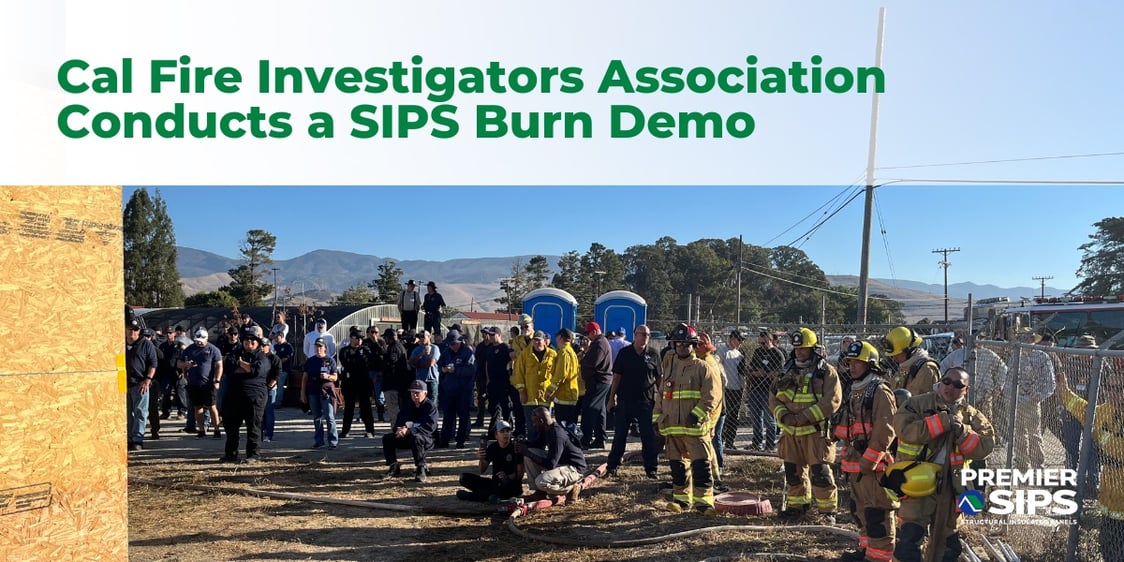

Ensuring the safety and resilience of buildings and their occupants is paramount for any contractor. Structural Insulated Panel Systems (SIPS) are a revolutionary building solution, offering a trifecta of benefits: energy efficiency, durability, and exceptional resilience against disasters, particularly fires. With their ability to pass critical fire tests, SIPS create airtight structures that significantly reduce the risk of fire spread within interior spaces. Keep reading below for the most common questions about SIPS and their fire behavior properties, and to see the results of a SIPS burn demonstration hosted by the California Fire Investigators Association & Premier SIPS.

Structural Insulated Panels Systems (SIPS) are commonly used to build energy-efficient structures that are built to last. These panels are categorized as Type V Combustible construction and require thermal barrier protection to guarantee the safety of its occupants in the event of a fire. Properly installed thermal barriers on SIPS have proven to perform better than wood stud construction. In the event of an uncontrolled fire, the organic component materials of SIPS will emit combustion products similar to those of typical wood construction.

Have questions about SIPS and fire performance? Or interested in exploring our case studies of projects that have performed in unfortunate fires, and the many others who have chosen to build with SIPS in fire prone areas? Reach out to us today and we will be happy to answer all your SIPS questions.

This information is presented as a summary of SIP technology and is not intended as full disclosure of SIPs information. Extensive testing and research has been conducted on SIPs concerning fire performance, toxicity of components, and structural capacities. Please contact Premier for additional technical information.

Comparing two key assemblies designed to combat airtightness. Learn how integrated envelope design improves energy..

Labor conditions vary from job to job. Learn how systems-based design supports consistent building performance despite..

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.