Why Every Building Must Manage Moisture, Regardless of Climate

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

The International Code Council (ICC) publishes the International Energy and Conservation Code (IECC). Over the last decade of ICC’s code issuing cycles, the IECC has permitted what we believe to be the most appropriate method for determining the performance values for exterior envelopes. The “U-factor Method” is the ideal alternative path for calculating thermal insulation requirements of High Performance Building Envelope systems like Structural Insulated Panels (SIPs). The IECC refers to the U-factor Method as the "U-factor Alternative Method of Compliance."

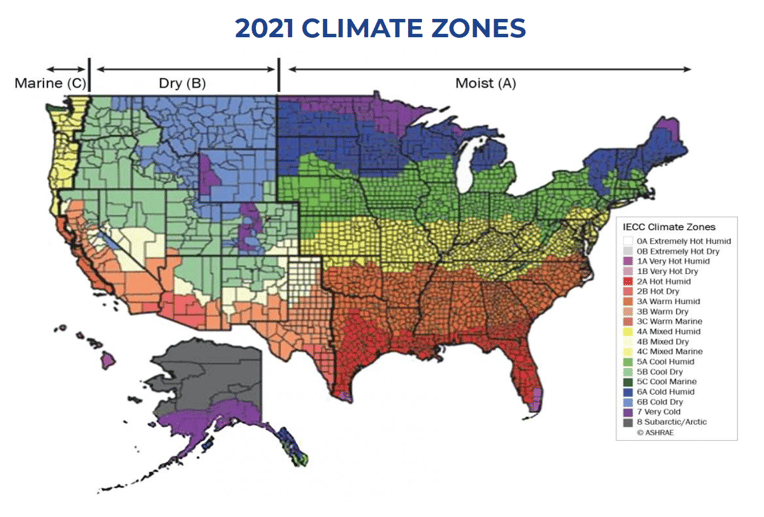

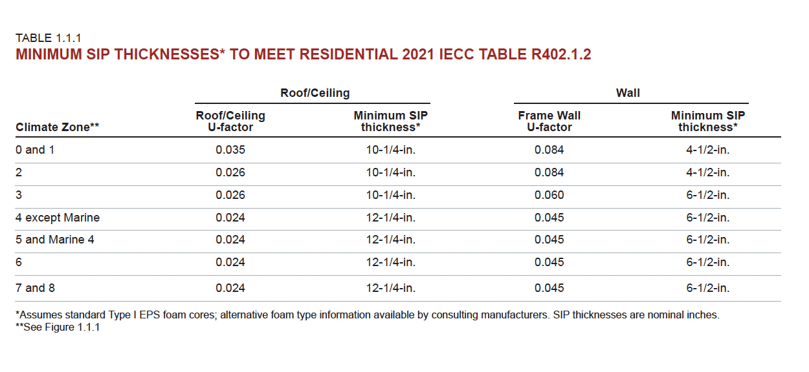

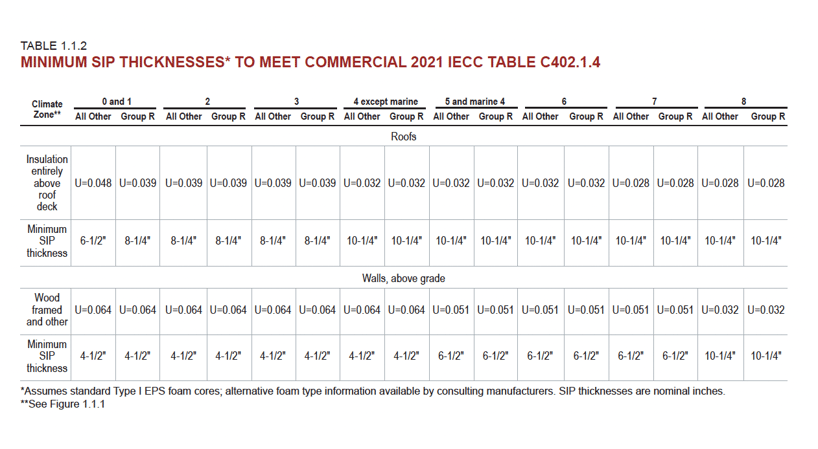

U-factor calculations are component based (a summation of the U-factor calculations for each individual layer) to demonstrate that an assembly complies with the IECC's intention of continuous insulation requirements. To ensure U-factor compliance, the most current 2021 version of the IECC (within both its Residential & Commercial Provisions in Chapter 4), which includes useful tables providing U-factor maximums (the lower your U-factor number, the higher the R-value) for all climate zones in the US, including Alaska and Hawaii. For the purpose of calculating U-factor needs for Premier SIPS, refer to Technical Bulletin (BC-1).

It’s simple really, when you use the U-factor Method you are able to include the R-value contribution of all the materials in the wall or roof/ceiling assembly. All building materials have an R-value, even inside and outside air provides an R-value “film” (we can also think of this film as a layer of air) that can be included in the overall R-value computation. A U-factor is simply the reciprocal of the sum of the R-values of air films and all the materials of construction.

Here’s a simple residential wall assembly example:

To determine the U-factor (U-value): 1 ÷ 24.73 = 0.040

Referring to the IECC, Residential Provisions, Chapter 4, Table R402.1.2 You’ll see that this 6.5” SIP wall and its air films and cladding materials has a U-factor that exceeds the IECC U-factor requirements in all Climate Zones from 0 to 8, 8 being the coldest zone in the US. Premier's Technical Department has put together this helpful Technical Bulletin (BC-1) to assist in determining U-factor compliance for residential and commercial applications by climate zone.

Combining the U-factor Method, with the use of SIP walls and roof/ceilings, provides the benefit of meeting the performance values required of the 2021 IECC, while keeping the wall thickness to a minimum , eliminating the need to use a Continuous Insulation overlay added to conventional framing, which costs extra labor and increases the wall thickness.

SIPs comply with the intention of continuous insulation required in the 2021 IECC by using this Add these U-factor benefits to the faster, stronger, greener construction that is delivered by Premier SIPs and you have a winning labor/time saving and energy reducing building solution to meet the ever-increasing demands of the Energy Building Codes!

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

A field perspective on SIP construction details, best practices, and common questions—from panel connections to electrical..

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.