Lumber Prices Are Volatile — SIPs Slash Costs and Risk

Lumber tariffs driving up costs? SIPs cut lumber use by up to 80%, lower labor needs, and deliver stronger, faster, more..

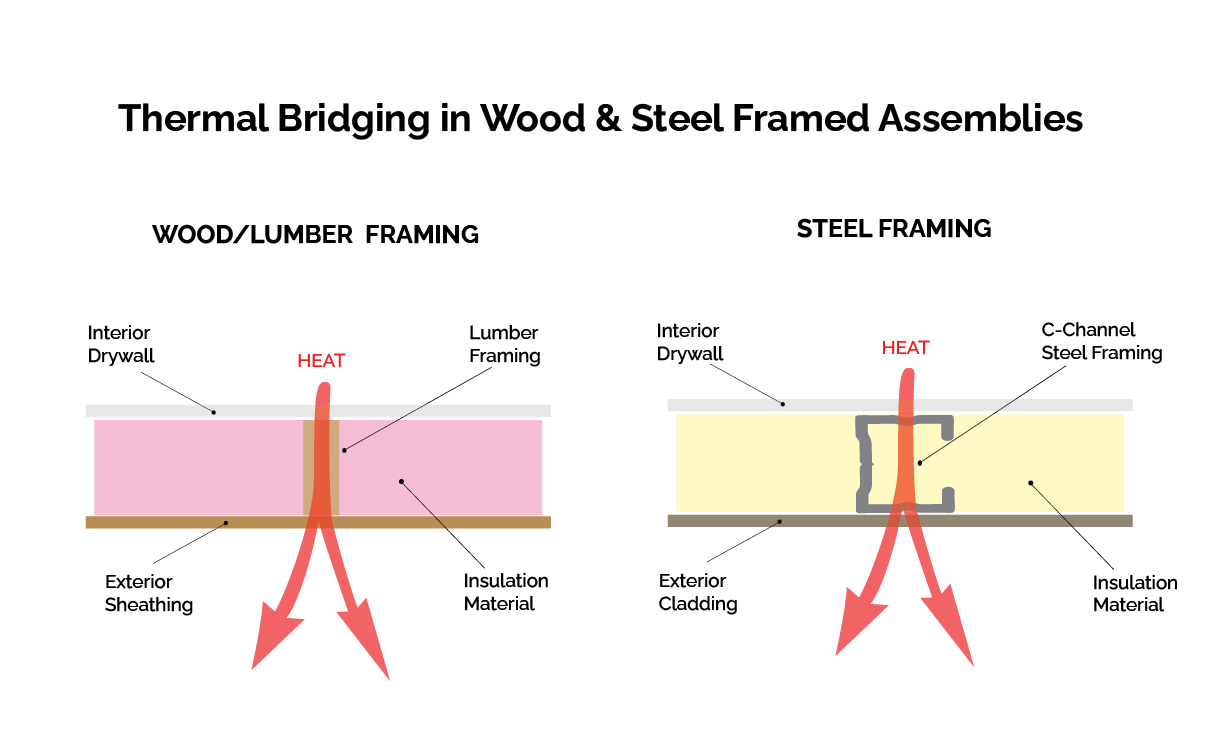

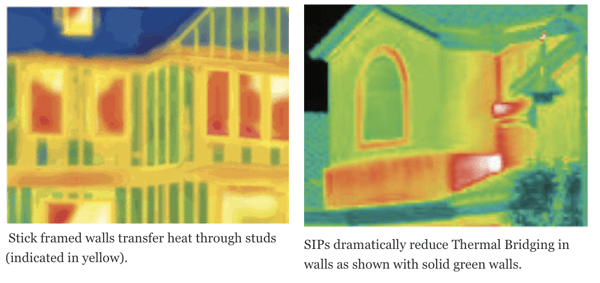

Simply described, it’s heat moving through high conducting materials. Like a metal spoon, in a hot pot of liquid where heat transfers from the pot/liquid to the spoon, heat transfers through many different materials.

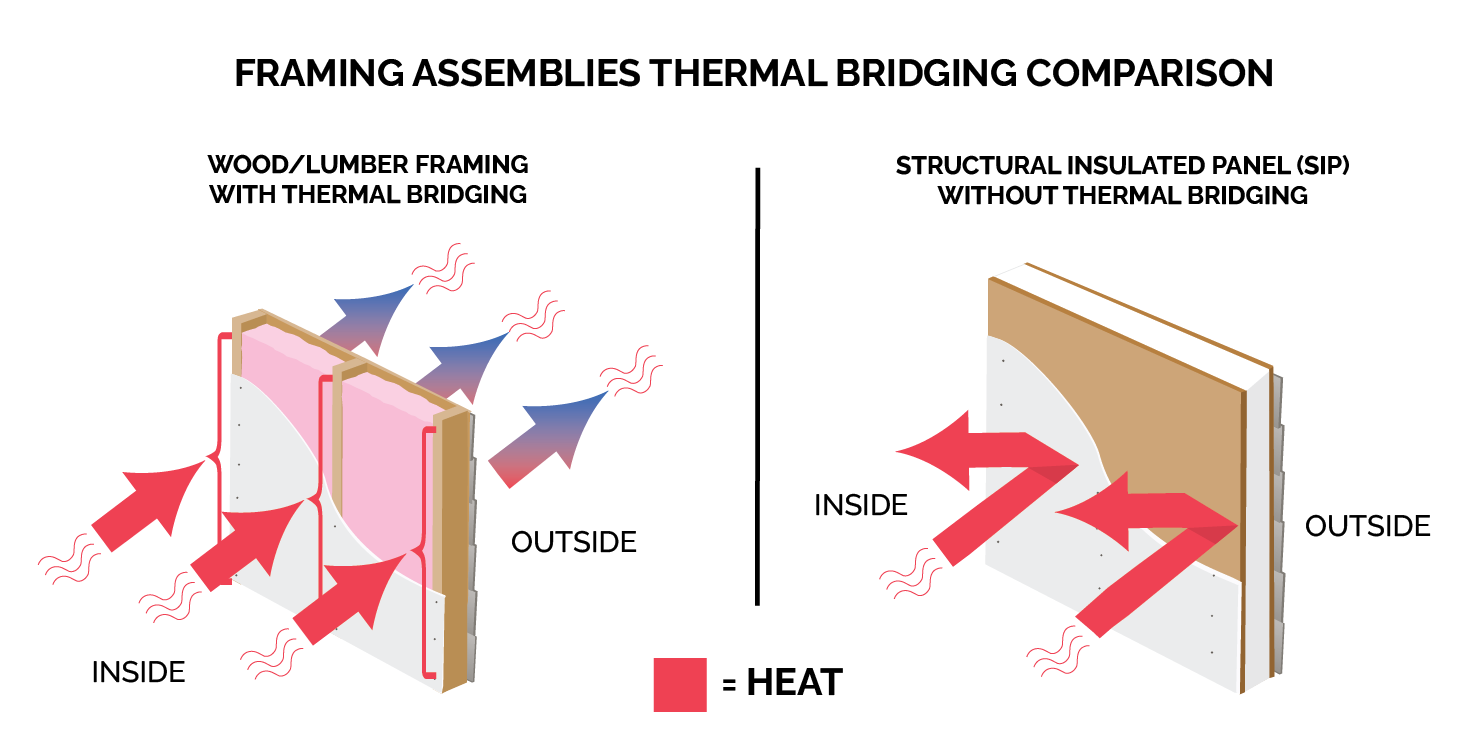

Framing members of wood, steel or masonry (each have heat conducting characteristics) that are not “disconnected” from the interior to the exterior of a structure form a thermal bridge. When there is something that blocks the bridge from inside and outside of a building, this is referred to as a “thermal break,” where the bridge for heat to travel is truly broken.

Framing members of wood, steel or masonry (each have heat conducting characteristics) that are not “disconnected” from the interior to the exterior of a structure form a thermal bridge. When there is something that blocks the bridge from inside and outside of a building, this is referred to as a “thermal break,” where the bridge for heat to travel is truly broken.

There is no such thing as cold, only the absence of heat. Heat always travels to where it can equalize. In structures, inside heat moves through framing members from the inside to the outside in winter and then reverses and moves from outside a structure to inside in the summer….relentlessly trying to equalize. The term for this heat movement in structures, again is called Thermal Bridging. Heat also conducts through windows and doors, but for our discussion we’ll be focusing on framing members.

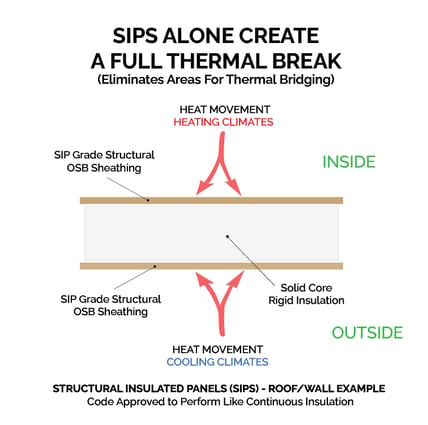

Thermal Bridging is a well known phenomenon by the Building Science and Building Code communities. In recent years new building code requirements have been adopted to reduce Thermal Bridging (heat transfer/escaping) through framing members, that result in high energy costs and discomfort for occupants. The 2018 International Energy Conservation Code (IECC), for both Commercial and Residential structures each have a Chapter 4 where provisions are stated to properly insulate foundations, floor slabs, walls and roofs. In these Chapters there are Tables giving minimum R-values and U-Factors for the various Climate Regions throughout the US. The R-value Method Tables prescriptively call out for minimum R-values, achieved by the means of cavity insulation and an overlay of Continuous Insulation (Ci).

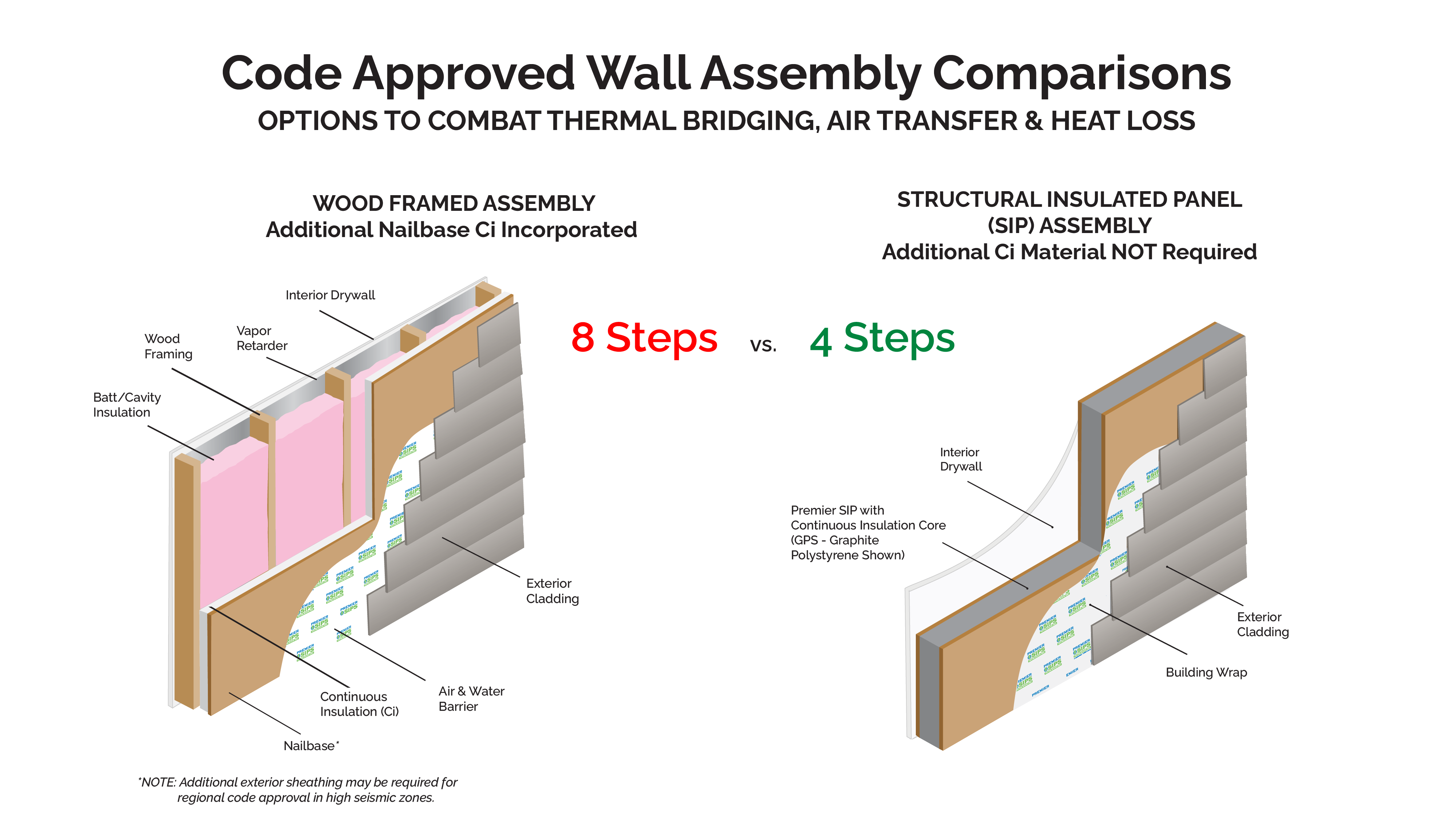

By definition and application, Ci overlays the outside of the framing materials, thereby creating an insulated thermal break (disconnection) between the inside and outside of the structure. The requirement for adding Ci is very effective for saving energy loss and increasing the interior comfort of the structure.

Although applying Ci is very beneficial to occupants of structures, many states, counties, and cities have not adopted this code requirement due to the negative push back from commercial/residential builders and building contractors. What is the basis of the objection from these builder groups? Ci assemblies create installation complexities, schedule delays, additional labor cost, higher material cost, a higher final building cost to the consumer, and a decrease in contractor profits.

In a number of ways Building Contractor’s concerns about meeting IECC requirements for Ci are warranted (MORE on 2021 IECC Codes here). The installation of Ci does present a challenge to the contractor community….who installs it? The framer…the siding contractor? Once this is decided, what is the best way to attach Ci attach to the exterior sheathing? How is the Weather Resistant Barrier (WRB) integrated into the assembly? How does it terminate? And at the termination points – windows, doors, mechanical penetration – how is it water drainage managed? Further, in many regions of the county it is required that "Rainscreen Drainage Planes" are necessary. Which leads to another challenge, and how to integrate a rainscreen when Ci application is now required by the 2021 IECC building code?

All this said, there is a widely available commercial and residential framing system assemblies that offers an eloquent and simple solution that meets the necessary insulation requirements of the 2021 IECC, WITHOUT additional continuous insulation [MORE on this here]. The easiest and most economical are Structural Insulated Panels (SIPS). As discussed in earlier articles, the 2021 IECC code allows for the calculation by the U-Factor Method to provide for proper insulation performance of walls and roofs, of which SIPS comply with performance without an extra layer of Ci. Because SIPS provide the structural component (structural grade OSB inner and outer facings are structurally laminated to a strong rigid solid insulation core), once installed as insulated walls and roofs, there is no need to add additional insulation overlays to meet IECC code requirements. The U-Factor Method considers all of the materials of the SIP component assembly and their collective R-values to comply with energy code requirements [LEARN how]. SIPS and the simplicity of their composite make-up is all that is needed to meet IECC insulation requirements. Additionally, SIPS are easily detailed to accomplish rainscreen water management systems where climate zones dictate.

Common framing methods – wood, steel, masonry – plus the addition of Continuous Insulation (Ci) result in application complexity and final higher building costs. SIPs, with their simplicity of composite make-up and ease of installation, needing no additional Ci appliqué, perform better at lower final building cost.

Explore more about the cost savings and budget comparisons with SIPS vs site wood framing assemblies that comply with IECC Ci requirements here.

For more information about the benefits of the SIP building system, visit this page.

Lumber tariffs driving up costs? SIPs cut lumber use by up to 80%, lower labor needs, and deliver stronger, faster, more..

SIPs deliver proven energy savings. Third-party studies show 40–60% lower energy use, smaller HVAC loads, and long-term..

While adding Ci to wood-framed construction is an effective way to improve energy efficiency, SIPs naturally meet and..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.