Why Every Building Must Manage Moisture, Regardless of Climate

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

What is the cost comparison between SIPs and sticks? We get this question a great deal. In this blog post, we break down the cost differences and show you why structural insulated panels (SIPs) are the more durable, easy to install, energy-efficient, and affordable option.

When it comes to SIP panels, the cost can vary depending on various factors, including the size and thickness of the panels, the type of insulation material used, the complexity of the design, and the region where you are located. Additionally, the supplier or manufacturer you choose may also influence the pricing.

When it comes to SIP panels, the cost can vary depending on various factors, including the size and thickness of the panels, the type of insulation material used, the complexity of the design, and the region where you are located. Additionally, the supplier or manufacturer you choose may also influence the pricing.

On average, SIP panels can range from $10 to $18 per square foot for materials. However, it's important to note this is a rough estimate.

While it includes full insulation and sheathing on both the interior and exterior, this cost estimate does not factor in time savings or reductions in ancillary costs that SIPs help deliver. Nor does it incorporate the real benefits of a high-performance building envelope with extensive energy savings (40-60% on average), quieter surroundings, greater comfort, and a healthier living environment.

To get an accurate cost estimate and comparison of the cost benefits of an offsite framing system like structural insulated panels, it’s recommended to reach out to a SIPs manufacturer, like Premier SIPS, directly and provide them with detailed information about your construction plans. We can offer more precise pricing based on your specific needs and preferences.

Comparing the cost of SIP panels to that of stick framing is a bit like trying to compare apples to oranges. It doesn’t work unless you compare all of the elements — the core, fruit, seeds, skin, and benefits of each.

Comparing the cost of SIP panels to that of stick framing is a bit like trying to compare apples to oranges. It doesn’t work unless you compare all of the elements — the core, fruit, seeds, skin, and benefits of each.

We often get questions like, “How much will a SIP package cost for a 1,800-square-foot home?” But the answer isn’t exactly straightforward. To determine SIPs pricing, you’ll need to consider how tall the walls are, the state or country in which you’re building, whether you plan on building in the next ten years, and many other factors.

The animation below illustrates how costs stack up between the two assemblies and is part of a current presentation created with the help of an engineer from Wright Engineers, a nationally recognized firm, who used to build with SIPs and lives in a SIP home, meaning he knows the product well.

As an American Institute of Architects (AIA) continuing education provider, we focus much of our CEU-approved education on how to compare costs and design and construct offsite SIP framing assemblies.

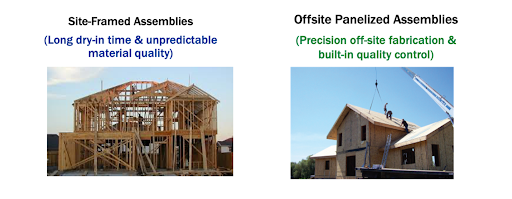

In the animation above, a cost and time comparison bar graph compounds. Looking at a house or building, when you first compare a stack of SIPs to a stack of 2x4s, the SIP stack will cost slightly more. This is primarily because the SIPs come with engineered solid core insulation and structural grade sheathing already installed.

It’s also important to consider that SIPs inherently reduce the amount of lumber needed for a stronger structure (proven 55% stronger out of the factory). A SIP panelized building envelope is approximately 3-5% lumber versus 22-24% for 2x6 site framing methods.

Offsite Premier SIPS construction has approximately 80% less lumber than a stick-framed assembly, which is cost savings in itself.

There are a few other factors to consider in this cost comparison, the first being that with the SIP package, most of the labor is done in the factory.

At Premier SIPS, we cut all the SIPs to the proper length and width (per floor plans), and we will account for the window and door openings. With 2x4s, you will need to measure dimensional lumber, cut all sections to length in the field, and frame window and door openings.

Delivered to a job site ready to install, SIPs go up faster (structure, sheathing, and insulation all in one step) than site-framed structures. The large panels require less labor than sticks to install, saving time and money — while helping combat long-term skilled labor shortages.

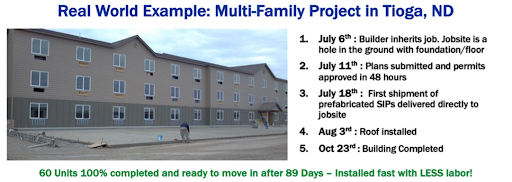

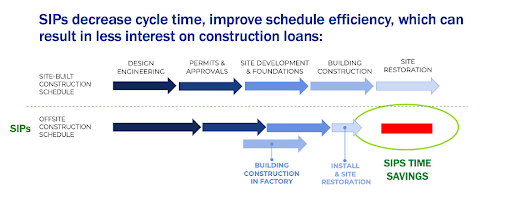

A faster installation means a reduction in potential carrying costs and interest paid on construction loans. A dried-in building enables other trades to install sooner and building occupants to move into a finished building faster.

The following illustrates the time savings realized because of SIPs' offsite fabrication:

After the SIPs or sticks are installed, this is when the cost gap between the two framing choices becomes apparent.

After you include the hardware like hold-downs, straps, and hurricane ties (the connection between the truss/rafter and the walls), the SIP package becomes less expensive. SIPs are stronger than your typical stick package, approved in all seismic and coastal zones, and require less hardware to be used in the building envelope assembly.

Additional cost savings are found in the ancillary benefits that a SIP structure delivers.

For example, it’s easier and less expensive to attach drywall and an exterior finish, such as stucco or siding. This is because engineered SIP wall, roof, or floor panels arrive straight and help builders deliver plumb square buildings every time.

Contractors don’t have to look for studs, as the structure is incorporated into each panel without dimensional lumber, saving time and money. Instead, you have a continuous nailing surface with structural grade-oriented strand board (OSB) skins on both sides of the SIPs.

The comparison animation also includes items like HVAC equipment (you can downsize with SIPs because of their energy efficiency and tightness) and waste disposal (less job site waste when building with SIPs as we cut them to the proper length and width in the factory, with window and door openings included).

Downsizing from a 3- to 2-ton HVAC system or saving 30% on waste disposal costs are regular cost savings per residential project with SIPs.

Additionally, electrical chases are pre-drilled in the factory enabling electricians to pull wire without extensive drilling through lumber (and potentially sacrificing structural integrity). An impressive case study comes from Manch Elementary in Las Vegas, where the electrical installation saved the project $1 million with factory-cut electrical chases.

After the building is complete, SIPs reduce builder callbacks significantly. This is because factory-engineered sections are delivered to the job site ready to install, reducing the errors of site-framed measuring. Factory-engineered SIPS also deliver straight large panels for reduced nail pops and easier installation for subs doors, windows, millwork, and cabinetry.

Solid core insulation reduces moisture inside wall and roof cavities (a leading cause of water, mold, and mildew issues). Additionally, a tight envelope without extensive gaps (such as lumber at all connection points) makes it harder for exterior contaminants to enter a building. This can be an upgrade for building owners.

Further enhancing a SIP envelope, the insulated core is treated for termite resistance, and the structural OSB also is manufactured with additives to treat for weathering and future fungal decay.

Premier SIPS are specifically clean air gold certified, providing additional indoor air quality (IAQ) benefits for many applications.

A systems warranty for a factory-fabricated SIP system is something that does not come with site-framed buildings.

Premier SIPS offers a 20-year structural and 50-year thermal warranty. This can deliver significant savings when builders don’t have to warrant or provide insurance on the structural components because it’s already done through the SIP manufacturer.

Energy-efficient building envelopes like SIPs qualify for significant energy tax incentives.

Federal incentives range from $2,500-5,000 per residential dwelling unit directly for the builder. For commercial projects, incentives can reach up to $5.00 per square foot to the building owner, architect, or engineer. State, county, city, and many utilities offer additional incentives per region.

Getting money back because you designed and built responsibly is a benefit to the bottom-line budget and the planet.

Finally, when using SIPs, the building’s operating costs will be much less — meaning you will have a more energy-efficient structure.

Finally, when using SIPs, the building’s operating costs will be much less — meaning you will have a more energy-efficient structure.

When comparing the cost of building with SIPs and sticks, SIPs should cost less, even before you consider energy savings, tax incentives, and trade benefits. This is especially true today, as lumber prices have skyrocketed since the COVID-19 outbreak began and continue to fluctuate with lumber mill shutdowns.

Skilled labor shortages (such as site-framing) are also a challenge throughout North America, and experts don’t see a fix for this any time soon.

We have an actual comparison based on two 2,500-square-foot single-family homes: one built with stick framing and one built using our SIPs.

We can share this detailed comparison with you, which shows that it costs less to build the house with SIPs. And this does not include huge energy savings, builder, building owner, or design professional energy efficiency tax incentives and rebates. It also does not include the current price escalations of building material components (lumber, steel, concrete, and more.)

Want to know the rough cost of building with SIP panels for your home? Reach out to a member of our team and we will be happy to help you with a price for a SIP package.

Want to know the rough cost of building with SIP panels for your home? Reach out to a member of our team and we will be happy to help you with a price for a SIP package.

Or if you’d like to see the entire presentation we mention above about engineering with SIPs, submit a presentation request and your local CEU-certified Premier Rep will be happy to coordinate a lunch and learn (we’ll bring lunch!) or a virtual session.

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

A field perspective on SIP construction details, best practices, and common questions—from panel connections to electrical..

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.