Proof #4: Certified Clean: SIPs and Healthier Indoor Environments

Discover how Premier SIPS support healthier buildings with low VOC emissions, Clean Air Gold certification, airtight..

.png?width=705&height=94&name=Tested.%20Proven.%20PREMIER%20(1).png)

Part 5 of the Proof in Performance Series – Solving Labor Challenges With Smarter Building Systems

Labor shortages and rising performance expectations are reshaping how the industry builds. Contractors are under pressure to deliver more work with fewer skilled workers—without sacrificing quality, precision, or schedule control. Structural Insulated Panels (SIPs) meet this challenge head-on.

In this final installment of our Proof in Performance series, we examine real-world research, including the industry-recognized RSMeans Time & Motion Study and multiple Premier SIPs case studies, all demonstrating how SIPs reduce installation time, simplify sequencing, and lower total installed cost.

>> Read Part 1: Why SIPs Are Stronger by Design

>> Read Part 2: Real-World Energy Savings

>> Read Part 3: Disaster Resilience That’s Real

>> Read Part 4: SIPs & Healthier Indoor Environments

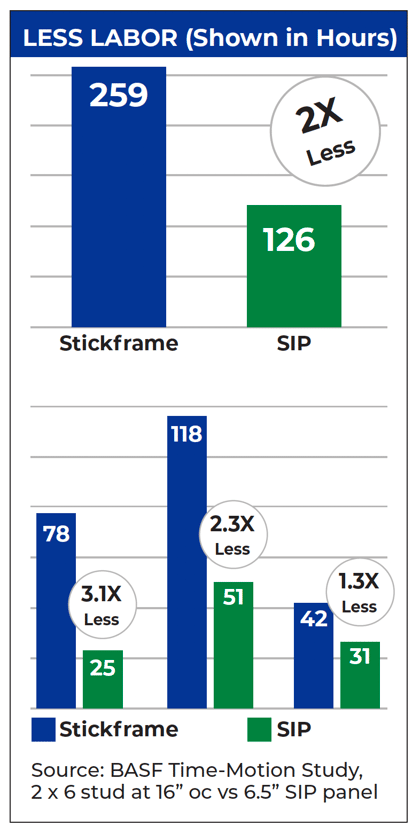

The gold standard in construction labor research—RSMeans—conducted a direct comparison between two identical 2,500-square-foot homes:

The findings were unmistakable.

What it studied: Labor hours and installation time required for structural framing, sheathing, and insulation in SIP vs. stick-framed construction.

What it found:

Key takeaway: SIPs cut installation time nearly in half, delivering one of the most labor-efficient envelope systems available today.

⇒ Learn More: The RSMeans SIP Time & Motion Study (PDF)

Stick framing requires coordination between four or more trades:

SIPs combine all of these steps into one installation with one crew.

What it studied: Trade consolidation and the labor burden removed when structure, insulation, and sheathing are integrated.

Key takeaway: SIPs eliminate multiple trade dependencies, reducing labor bottlenecks and simplifying scheduling.

SIPs accelerate the critical path by delivering structure + sheathing + insulation in a single phase. This allows mechanical, electrical, and plumbing crews to begin sooner—saving days to weeks.

Premier project data shows:

This installation speed aligns with the timeline improvements highlighted in Part 2: SIPs vs. the Clock & Thermostat.

Key takeaway: SIPs deliver earlier dry-in, shorten the schedule, and reduce downtime between trades.

SIPs arrive pre-cut and engineered, which drastically reduces construction site waste.

SIPs arrive pre-cut and engineered, which drastically reduces construction site waste.

Typical reduction: 30–50% less waste

Advantages:

Key takeaway: SIPs reduce both material waste and the labor required to manage it.

With factory-controlled manufacturing, SIPs minimize common issues that plague stick-built projects:

These quality improvements connect directly to Part 4 of this series, where SIPs consistently achieved ≤1.0 ACH50, outperforming framed construction during blower-door testing.

Key takeaway: SIPs reduce call-backs by eliminating many craftsmanship variables upfront.

Premier SIPs documented installation time, crew size, and sequencing across three representative builds—a duplex, a single-family residence, and a 28'×22' structure. These real-world projects validate the measurable labor savings indicated by RSMeans.

Case Study 1: Two-Unit Duplex

Crew size: 3 installers

Crew size: 3 installers

Scope: SIP walls and roof

What it studied: Installation time for walls and roof panels across two identical units, comparing observed duration to traditional framing expectations.

What happened:

Key takeaway: Small crews can rapidly erect large structures, even in multi-unit housing.

Case Study 2: Single-Family Residence

Crew size: 4 installers

Crew size: 4 installers

Scope: Complete SIP shell (walls + roof)

What it studied: Real installation time for a standard home using SIPs versus the builder’s estimated hours for stick framing.

What happened:

Key takeaway: SIPs reduce shell construction time dramatically—lowering labor costs on every standard home.

Case Study 3: 28'×22' SIP Structure

Crew size: 3 installers

Crew size: 3 installers

Scope: SIP walls + roof

What it studied: Labor efficiency on a small building footprint—ideal for comparing SIP vs. stick framing on scalable or accessory structures.

What happened:

Key takeaway: SIPs simplify installation even on compact projects, confirming predictable labor savings at every scale.

⇒ Learn More: Premier SIPS Labor Case Studies (PDF)

When comparing material cost alone, SIPs may appear higher. But when evaluating total installed cost, SIPs routinely outperform traditional framing because they deliver:

Key takeaway: SIPs reduce total project cost by improving labor efficiency AND long-term building performance.

Across independent studies and real-world builds, one conclusion is clear: SIPs deliver predictable labor, installation, and cost advantages that traditional framing cannot match.

Across independent studies and real-world builds, one conclusion is clear: SIPs deliver predictable labor, installation, and cost advantages that traditional framing cannot match.

When combined with the strength, resilience, energy savings, and health benefits documented throughout this series, SIPs provide a compelling pathway for builders seeking greater efficiency and profitability in a constrained labor market.

How much faster do SIPs install than stick framing?

RSMeans found SIPs install 55% faster, saving 130 labor hours on a typical home.

Do SIPs require special installation crews?

No. Standard carpentry skills are sufficient. Premier provides training and detailed shop drawings.

Do SIPs reduce the number of trades on site?

Yes. SIPs replace framing, insulation, sheathing, and air-sealing operations.

Is the cost difference worth it?

Yes. SIPs often deliver lower total installed cost thanks to reduced labor, shorter schedule, and fewer callbacks.

Do smaller projects still see labor savings?

Absolutely. The 28'×22' case study shows SIPs drastically simplify installation even on compact structures.

Do faster installs compromise quality?

No. Factory precision increases quality and consistency while reducing rework.

Want more? Head to the Premier SIPS Resource Portal to explore full studies, test data, technical documents, code reports, and more. Contact your local Premier SIPS Advisor to discover how SIPs can simplify labor, reduce time, and create more predictable, profitable construction outcomes.

Discover how Premier SIPS support healthier buildings with low VOC emissions, Clean Air Gold certification, airtight..

Lumber tariffs driving up costs? SIPs cut lumber use by up to 80%, lower labor needs, and deliver stronger, faster, more..

Discover how SIPs withstand wildfires, earthquakes, and hurricanes—backed by FEMA, USDA, and APA testing for proven disaster..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.