Proof #5: Less Labor, Faster Installs, Smarter Builds: SIPs vs. Traditional Framing

Discover how SIPs cut installation time by 55%, reduce labor needs, and lower total project costs. See real data from RS..

.png?width=698&height=93&name=Tested.%20Proven.%20PREMIER%20(1).png)

Part 4 of the Proof in Performance Series – Building Solutions That Keep Occupants Safe and Healthy

High performance isn’t just about strength or energy savings; it’s also about how a building supports the people inside it. Premier SIPS are engineered, tested, and certified to support healthier indoor environments. With low-VOC materials, airtight construction, and proven moisture control, SIPs are a trusted solution for architects, builders and building owners prioritizing indoor air quality (IAQ) and occupant well-being.

From schools and healthcare facilities to homes and offices, Premier Structural Insulated Panels, SIPS, go beyond structure and efficiency; they help create healthier indoor environments. Our panels are engineered with clean materials, tested for low emissions, and certified to meet some of the most rigorous indoor air quality standards in the construction industry.

This installment of our Proof in Performance blog series highlights third-party testing and certification that verify how SIPs contribute to better IAQ and occupant well-being.

Explore More Proof in Performance

>> Read Proof in Performance Part 1: Structural Performance, Why SIPs Are Stronger by Design

>> Read Proof in Performance Part 2: Energy Efficiency: Real-World Energy Savings

>> Read Proof in Performance Part 3: Disaster Resilience: Proven Strength Under Pressure

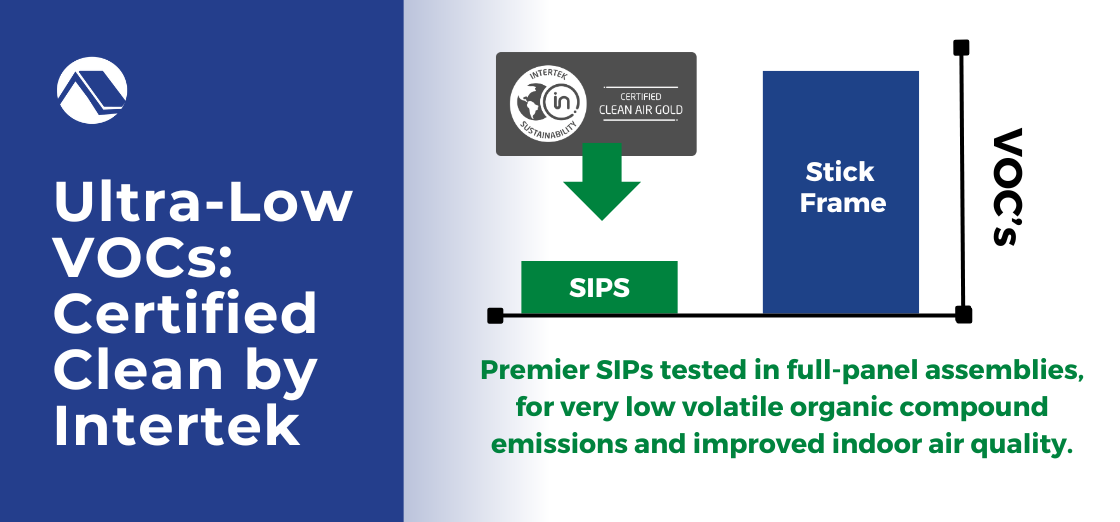

Premier SIPS are third-party tested and certified Clean Air Gold by Intertek. This designation verifies ultra-low VOC emissions and compliance with the industry’s most stringent indoor air quality standards for many building applications.

The Clean Air Gold certification process places SIP assemblies in an environmental chamber, where air samples are continuously tested for volatile organic compounds (VOCs) and other emissions over several weeks. This ensures the entire SIP system—not just its individual components—meets healthy building standards.

The Clean Air Gold certification process places SIP assemblies in an environmental chamber, where air samples are continuously tested for volatile organic compounds (VOCs) and other emissions over several weeks. This ensures the entire SIP system—not just its individual components—meets healthy building standards.

What it studied: VOC emissions from complete SIP assemblies, including OSB facings, EPS insulation, and adhesives.

Key takeaway: Premier SIPS meet Clean Air Gold certification for low-emitting materials—providing healthier indoor environments for schools and workplaces.

⇒ Learn about the Clean Air Gold Certification

Formaldehyde emissions are often a concern with engineered wood materials—but modern EWPs, including the structural OSB used in SIPs, are designed to meet or exceed the strictest emission standards.

The APA’s Technical Note J330 explains that structural wood panels like OSB are manufactured using phenol-formaldehyde or isocyanate adhesives, which emit such low levels that they are exempt from the world’s most recognized emission regulations, including:

What it studied: Formaldehyde emissions from engineered wood products and their compliance with leading international standards.

Key takeaway: SIPs made with structural-grade OSB meet low-emission requirements and are exempt from the most stringent formaldehyde regulations, confirming their safety for indoor use.

⇒ Read APA Technical Note J330: Formaldehyde and Engineered Wood Products

The expanded polystyrene (EPS) insulation used in Premier SIPS contains no formaldehyde, chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), or other ozone-depleting substances. EPS is chemically inert and non-off-gassing once manufactured, helping maintain a stable and healthy indoor environment.

EPS also contributes to cleaner air through its long-term durability—it doesn’t degrade, rot, or support mold growth under normal building conditions. As documented by the EPS Industry Alliance, EPS insulation supports sustainability goals by offering low emissions, high recyclability, and long service life.

Additionally, lifecycle data published in the SIPA Environmental Product Declaration (EPD) confirms that SIPs using EPS cores demonstrate low embodied environmental impact and contribute to improved indoor air quality across a building’s lifespan.

What it studied: Emission characteristics, lifecycle impacts, and sustainability performance of EPS insulation used in SIP assemblies.

Key takeaway: EPS is an inert, non-toxic insulation with zero off-gassing, long-term stability, and documented sustainability benefits—making it ideal for healthy, airtight structures.

⇒ Read More From the EPS Industry Alliance

⇒ Read SIPS Reduce Global Warming: Life Cycle Benefits of SIPS

⇒ Read the Environment Product Declaration for EPS Insulation

Healthy indoor air also depends on controlling moisture. SIPs’ airtight construction minimizes uncontrolled air infiltration, which helps prevent condensation, mold, and pollutant entry. When paired with mechanical ventilation systems like HRVs or ERVs, SIP buildings achieve an ideal balance of airtightness and fresh-air circulation.

What it studied: The role of SIP airtightness in moisture prevention and IAQ improvement.

Key takeaway: SIPs’ tight envelope prevents moisture accumulation and airborne contaminants—supporting cleaner, more comfortable living spaces.

⇒ Learn More and Download Premier’s Design Best Practices for HVAC and Ventilation

Cleaner air doesn’t happen by accident, it starts with what you build with. Premier SIPS deliver verified low-VOC performance, airtight construction, and healthier indoor environments backed by independent testing.

If you’re designing schools, multifamily, commercial spaces, or high-performance homes, choosing certified clean materials from the start makes all the difference. Our team is here to help you build smarter from the inside out.

Read on for quick answers to the most common questions architects, builders, and homeowners ask about SIPs and indoor health.

What makes SIPs healthier for indoor air quality?

Premier SIPS use low-emitting OSB, inert EPS insulation, and clean adhesives, and are certified Clean Air Gold for ultra-low VOCs.

Do SIPs off-gas?

No. EPS insulation cores contain no formaldehyde or harmful chemical blowing agents, and structural OSB used in SIPs meets or exceeds international low-emission standards.

Are SIPs good for people with asthma or allergies?

Yes. Airtight SIP envelopes reduce pollutants, allergens, and moisture infiltration when paired with proper ventilation.

What certifications should architects look for when specifying healthy materials?

Clean Air Gold, EPD (Environmental Product Declaration), and compliance with CARB, HUD, and EN formaldehyde standards.

Discover how SIPs cut installation time by 55%, reduce labor needs, and lower total project costs. See real data from RS..

Discover how SIPs withstand wildfires, earthquakes, and hurricanes—backed by FEMA, USDA, and APA testing for proven disaster..

SIPs deliver proven energy savings. Third-party studies show 40–60% lower energy use, smaller HVAC loads, and long-term..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.