Why Every Building Must Manage Moisture, Regardless of Climate

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

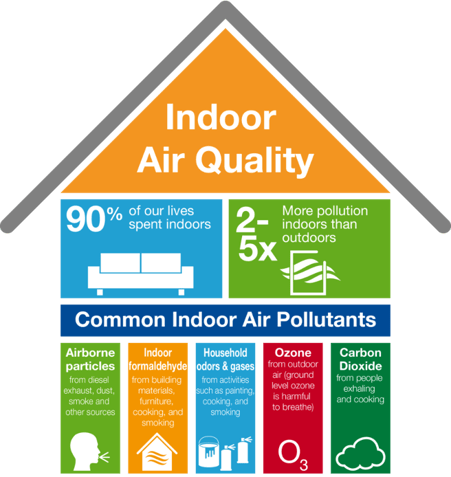

During this interesting period in time, many Americans are still clocking work hours in the comfort of their homes. North Americans, on average, spend 90% of time* indoors.

During this interesting period in time, many Americans are still clocking work hours in the comfort of their homes. North Americans, on average, spend 90% of time* indoors.

People most susceptible to the adverse effects of pollution (e.g., the very young, older adults) spend even more time indoors. Indoors can also be a refuge from poor outdoor air quality (such as in dense cities or forest fire areas). In fact, the American Lunch Association reports that an astonishing 137 million Americans live in places with failing grades for unhealthy levels of ozone or particle pollution, putting their health at risk. Add to this 36 million are also at high risk living with Asthma or COPD lung diseases, and we know there is a high correlation between Coronavirus & indoor air quality (IAQ).

Awareness to air quality & indoor environments has increased – for the good & bad. But the indoor air quality of a building does not always provide a safe haven, as concentrations of pollutants are often 2 to 5 times higher than outdoors*. Building interior gasses and chemicals can trigger asthma-related issues and cause headaches, eye irritation, and allergies. Sometimes detrimental health issues, like cancers, can even be attributed to household toxins. The indoor environments where people spend time to work (offices), stay (lodging), shop (retail), learn (schools) must address IAQ (indoor air quality) in the design process.

With this in mind, it does provide some comfort to know that building with an impermeable building envelope like structural insulated panels (or SIPs) deliver much healthier indoor air quality levels than traditional stud/stick framed structures. Add to this is the peace of mind that Premier SIPS are Indoor Air Gold certified.

Indoor air quality, or IAQ, is a vital component of a healthier, more comfortable indoor/living environment. Improved IAQ can significantly reduce respiratory issues, allergens, and exposure to harmful bodily toxins.

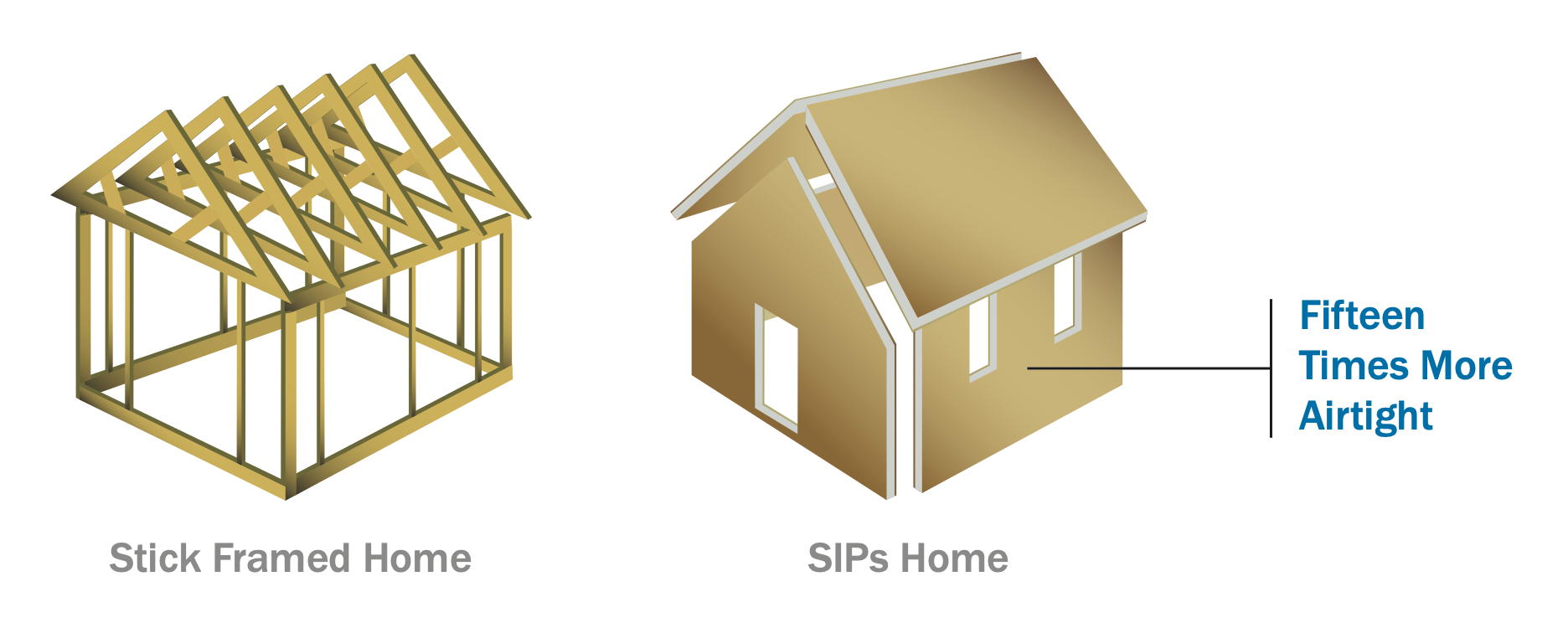

SIPs, expanded polystyrene (EPS) rigid foam insulation sandwiched between two oriented strand boards (OSB). Large monolithic panels are factory fabricated per floor plans and assembled together to form in sections of up to 8'x24' to reduce the number of joints to manage and provide a virtually airtight building envelope. Fewer joints equal fewer air leaks delivering a tight seal that is 15 times more airtight that stick framed structures. The airtight nature of a SIP building reduces unwanted contaminants from entering a building and allows for better control over indoor air quality.

While SIPs buildings do require controlled ventilation, it can be incorporated into a heating and cooling system for energy savings to further improves air quality by filtering out contaminants and allergens, allowing incoming air to be dehumidified, and thus, reducing the possibility of mold growth. Additionally OSB factory applications (zinc borate) or topical treatments (e.g. Frame Guard) reduce exposure to fungal decay.

Because of the non-toxic material used in SIPs insulation, mold and insects are further deterred from entering the home. The EPS or GPS MAX solid insulation core is inherently resistant to mold growth and moisture retention and is inset resistant.

Many states, counties, and cities now require building materials to be third-party certified as low VOC emitting materials. Premier SIPS have been tested to prove they are low VOC emitting (a critical attribute to achieving Clean Air Certification). SIPs do not contain any VOCs or other harmful chemicals that can affect occupant health. The components used to make SIPs (foam, oriented strand board, and adhesive) meet some of the most stringent standards for indoor air quality.

The Environmental Protection Agency concluded that the average U.S. home releases 22,000 pounds of toxic carbon dioxide into the atmosphere each year. To combat this statistic, many builders choose to build with SIPs because each facet of the manufacturing process is clean and will not disrupt the environment:

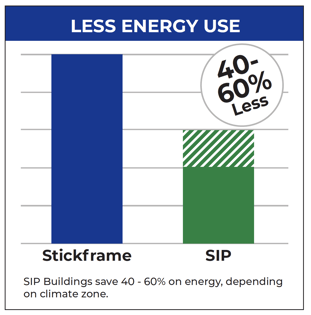

Because SIP Systems help prevent air drafts, this not only creates healthier environments but also has a massive impact on the energy consumption and emissions a building contributes. This leads to lower energy usage and reduced greenhouse gas emitted from each SIPs home, building, warehouse and structure. Tax incentives recognize the 40-60% energy savings and contributions to conserving resources, and SIPs buildings easily qualify for impressive tax credits and deductions (these change regularly by region, consult your local contact for specifics).

Because SIP Systems help prevent air drafts, this not only creates healthier environments but also has a massive impact on the energy consumption and emissions a building contributes. This leads to lower energy usage and reduced greenhouse gas emitted from each SIPs home, building, warehouse and structure. Tax incentives recognize the 40-60% energy savings and contributions to conserving resources, and SIPs buildings easily qualify for impressive tax credits and deductions (these change regularly by region, consult your local contact for specifics).

In utilizing SIPs, designers, builders and owners can feel proud that they’re doing their part to better the environment through reduced energy demand, while simultaneously ensuring healthy homes for families, young and old.

* US EPA (Environmental Protection Agency Report to Congress on indoor air quality: Volume 2. EPA/400/1-89/001C, and The total exposure assessment methodology (TEAM) study: Summary and analysis. EPA/600/6-87/002a. Washington, DC.

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

A field perspective on SIP construction details, best practices, and common questions—from panel connections to electrical..

High-performance buildings don’t rely on better materials alone. Learn why systems-based building envelopes deliver more..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.