Why Every Building Must Manage Moisture, Regardless of Climate

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

For decades, construction conversations have focused on materials: better insulation, stronger framing, smarter membranes. But building performance doesn’t improve by optimizing individual components in isolation.

Despite better products than ever, many buildings still miss energy targets, struggle with air leakage, or require oversized mechanical systems—not because materials failed, but because the building envelope was never designed to function as a whole.

In other words, building performance isn’t a product problem—it’s a systems problem.

High-performance buildings aren’t the result of a single product choice. They’re the result of how well the building envelope functions as an integrated system.

This distinction matters differently depending on your role.

For designers, it’s about reducing the gap between performance intent and real-world outcomes.

For builders, it’s about simplifying sequencing, coordination, and risk in the field.

Systems-based envelope design isn’t new. Integrated approaches like Structural Insulated Panels (SIPs) have been used successfully for decades. What has changed is the level of performance, predictability, and efficiency the industry now demands.

Learn more about high-performance envelope systems

Modern buildings are typically constructed using high-quality individual components, including:

Each product is designed to perform a specific function—and many perform that function exceptionally well. The challenge isn’t the materials themselves. It’s how those materials come together in practice.

This is where performance breaks down in the field.

Most building envelopes are assembled in layers, installed by different trades, at different times, and under varying jobsite conditions. Even when drawings describe a wall “assembly” as a system, real-world construction often turns it into a sequence of independent steps.

For example, a wall assembly may be fully code-compliant on paper yet still require oversized mechanical systems because air-sealing continuity was never resolved across interfaces as part of a single system.

As performance requirements increase, this fragmentation introduces uncertainty—making outcomes harder to predict, harder to verify, and harder to manage.

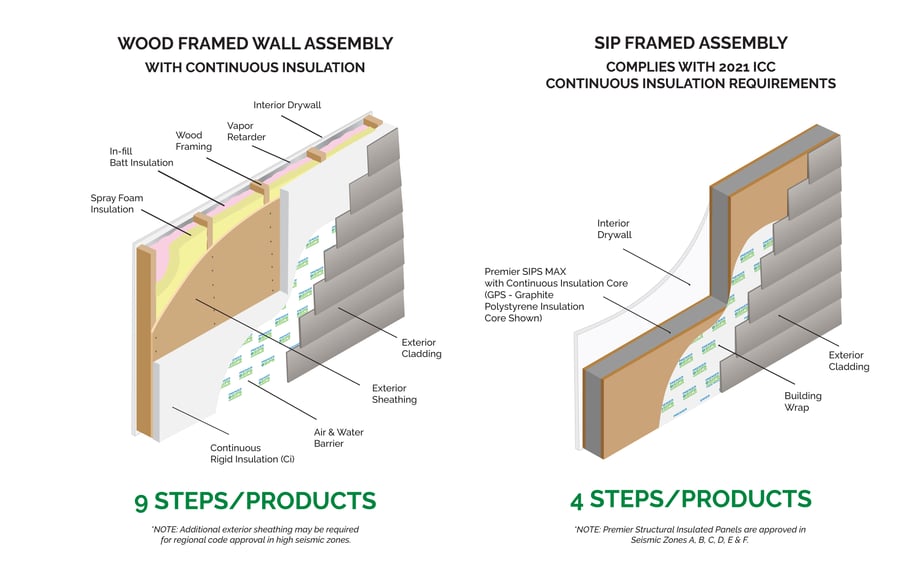

The difference between layered construction and systems-based design isn’t philosophical—it’s practical.

Traditional Layered Envelope (Field-Assembled)

As layers multiply, so do interfaces, inspections, and opportunities for variation in installation, sequencing, and coordination.

Systems-Based Envelope (Engineered Performance)

High-performance envelope systems are engineered so that structure, insulation, and air control are integrated rather than assembled sequentially. Instead of relying on perfect alignment in the field, performance is built into the system itself.

Layered Construction

Systems-Based Building Envelope

This distinction may appear subtle on drawings, but it has a significant impact on predictability, durability, and long-term building performance.

Explore how high-performance building envelopes differ from traditional layered assemblies

When the building envelope is designed as a system, performance advantages emerge naturally—not because of added complexity, but because critical functions are resolved upstream.

Designing the envelope as a system also changes how risk is managed.

Coordinated performance: Structural, thermal, and air-control roles are resolved together rather than competing for space or sequencing in the field.

Reduced air leakage and thermal bridging: Fewer transitions mean fewer opportunities for energy loss and moisture intrusion.

Factory-controlled precision: Critical tolerances are established upstream instead of relying solely on jobsite conditions.

Predictable outcomes: Airtightness and energy efficiency are measurable and repeatable.

Simplified construction: Fewer trades and fewer steps reduce labor risk and coordination challenges.

Structural Insulated Panels (SIPs) are a clear example of a systems-based building envelope solution.

See how SIPs streamline installation and reduce jobsite complexity.

SIPs are often described as a substitute for framing or insulation. In reality, SIPs represent a system, a fundamentally different approach to building envelope construction.

SIPs are often described as a substitute for framing or insulation. In reality, SIPs represent a system, a fundamentally different approach to building envelope construction.

Rather than layering components one at a time, SIPs integrate structural capacity, continuous insulation, and airtight construction into a single engineered panel.

As a result, critical performance characteristics are resolved during design and manufacturing—not dependent on a sequence of field-installed layers.

This integrated approach delivers practical, real-world advantages:

Because performance is inherent to the system, SIPs reduce reliance on flawless field sequencing. That design-level certainty helps teams manage risk and deliver more consistent outcomes across projects.

Learn why SIPs are often misunderstood - and how they differ fundamentally from conventional framing.

The benefits of a systems-based building envelope extend well beyond initial construction. Integrated envelope systems support:

These outcomes are not incidental; they are the result of systems-based envelope design.

Explore third-party research and verified data supporting systems-backed performance.

Before selecting individual envelope products, project teams should first decide whether the building envelope will be designed as a coordinated system or assembled in layers.

Buildings that perform best over time rely on integrated envelope systems designed for predictability, durability, and long-term efficiency.

Structural Insulated Panels reflect this shift. They offer a more complete, reliable approach to building envelope design—one that aligns performance goals with real-world results.

For teams designing high-performance homes, multifamily projects, or light commercial buildings—where predictability matters—systems-based envelopes offer a smarter path forward.

⇒ Talk with a Premier SIPS Advisor

A systems-based building envelope is designed so that structural support, insulation, and air control work together as an integrated system rather than as separate, sequential layers. Performance is resolved during design and manufacturing instead of relying on perfect alignment and sequencing in the field.

Traditional layered assemblies rely on multiple products installed by different trades at different times. Overall performance depends on coordination and execution in the field. Systems-based envelopes integrate critical functions into fewer components, reducing interfaces, variability, and performance risk.

High-quality materials can underperform when envelope components are assembled as disconnected parts. Misaligned air barriers, thermal breaks, and sequencing issues often introduce air leakage and thermal loss that were not resolved as part of a coordinated system.

Yes. SIPs integrate structure, continuous insulation, and airtight construction into a single engineered panel. This allows key performance characteristics to be designed and verified upstream rather than assembled layer by layer in the field.

Systems-based envelopes change how cost is evaluated. Rather than focusing on individual material costs, they shift the conversation toward total project predictability, reduced coordination risk, simplified construction, and long-term performance outcomes.

Integrated envelope systems deliver measurable airtightness and thermal performance, making it easier to comply with increasingly performance-based energy codes. By reducing heating and cooling loads, they also support electrification and decarbonization strategies.

Architects benefit from improved alignment between design intent and built performance. Builders benefit from simplified sequencing, fewer trades, and reduced risk. Owners benefit from predictable energy use, durability, and long-term operating performance.

Envelope strategy should be established early in design. Before selecting individual products, project teams should decide whether the building envelope will be designed as a coordinated system or assembled from layered components.

SIPA provides educational resources, technical guidance, and third-party research on systems-based envelope design and Structural Insulated Panels.

⇒ Explore SIPA education and resources

⇒ SIPs Advantages for Design & Construction Teams

Discover why managing moisture in every building is crucial for performance and durability, regardless of climate, with..

A field perspective on SIP construction details, best practices, and common questions—from panel connections to electrical..

2026 Builder Outlook: See the top construction trends—labor, codes, offsite growth, IAQ, cost stability—and how SIPs help..

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.