Alakanuk School

Educational | Kirkland, WA | SIPs Jr. High School

Washington

Project Type Commercial | Education/Schools

Year Completed 2011

Project Size 115925 sq ft

SIPS Used 10" Roof & 6" Walls

Environmental Certifications Net Zero/Zero Energy Ready

Awards 2012 SIPA Building Excellence

Architect Mahlum Architects

Contractor Babbit Neuman Construction

Project Overview

Premier SIPS Help Create a Tight, Well-Insulated Building Envelope for Finn Hill Environmental & Adventure School in Kirkland, Washington.

Finn Hill Junior High is a new, 120,000 square foot school with approximately 30 faculty and 430 students in grades 6-8. The $29,400,000 building is designed to Washington Sustainable School Program specifications and features 24 general classrooms, 5 science classrooms and 6 specialized classrooms including special education, fine arts, technology and a media center. The school, completed in 2011, also houses the regional production kitchen.

When it came time to replace the aging Finn Hill Middle School in Kirkland, Washington, the Lake Washington School District took the opportunity to build a cutting edge school that demonstrates the district’s leadership in energy efficiency, sustainability, and progressive learning environments. They partnered with Seattle-based architecture firm Mahlum to craft an innovative zero-energy-ready design that harnesses the efficiency of a structural insulated panel (SIP) building enclosure and exceeds the ENERGY STAR median by nearly 50 percent.

The 6" SIP wall and 10" SIP roof panels used to frame the structure helped the Lake Washington School District reduce energy costs, and allow for smaller, more cost-effective mechanical systems. Aptly named the "Environmental & Adventure School" students have been able to monitor energy use live through an interactive modeling feature within the school. Teaching energy awareness and conservation for the future!.

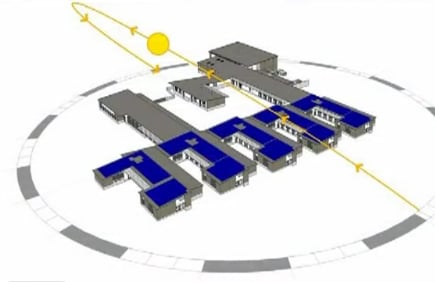

Reducing heating and cooling consumption was critical for the building’s “net-zero energy ready” design, meaning that the designs needed to maximize the potential area for the roof-mounted solar panels that would be sufficient to entirely power the school’s needs. When it opened it was the largest school solar installation and one of the largest solar panel installations in the state.

To meet the Lake Washington School District’s ambitious goal of a zero-energy-ready building, Mahlum calculated the proposed energy use intensity (EUI), or amount of energy the building will consume per square foot each year. For the Finn Hill Middle School, the design goal was 25 kBTU/sq. ft./yr., which is 47 percent lower than the ENERGY STAR median and more efficient than a typical school built to the building code.

According to Anjali Grant, an Associate at Mahlum, reaching this level of efficiency is not easy and requires a careful examination of all aspects of building design. The school is oriented so that every classroom receives balanced daylighting via operable windows and an integrated clerestory. Dimming sensors detect when natural light is present and adjust electric lights accordingly.

“If you walk through the building on a typical overcast day during the daylight hours you’ll find that most of the lights are off,” said Grant. “The quality of the light is better for teaching and learning, and the district reaps the benefit of the cost savings.”

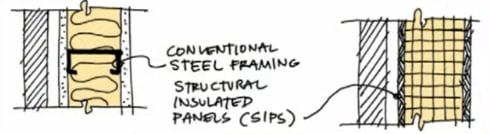

The next priority that Grant and her design team tackled was the building enclosure. They worked with structural engineering firm Coughlin Porter Lundeen to determine an enclosure system that would meet their thermal and structural performance requirements. After examining several options, they settled on structural insulated panels (SIPs) from Premier SIPs.

Prefabricated SIPs consist of an insulating foam core laminated between two structural facings of oriented strand board (OSB). SIPs deliver uninterrupted insulation with minimal thermal bridging while also establishing a continuous air barrier that limits convective losses through the building envelope.

“Thermal insulation is important and SIPs play a big role in that,” said Grant. “There are a couple of different goals with thermal insulation, one is just having that continuous rigid insulation around the exterior envelope, another one is reducing the infiltration, and yet another is pulling our structure inboard of the SIPs so we don’t have pieces of steel bridging the thermal gap.”

Placing structural elements inside the thermal envelope added an aesthetic element as well, exposing the school’s simple yet elegant glulam beam roof structure. The spanning capabilities of SIPs allowed the building to be designed based on a modular system of 14-ft. and 16-ft. spans, reducing both material waste and cost.

“When you start looking at SIPs, you can’t look at just SIPs versus a conventional wall,” said Grant. “SIPs allow me to reduce structure, they allow me to avoid installing continuous rigid insulation on the exterior walls, and when you add all those things together it starts to look more comparable, but you have to look at it more holistically.”

Beyond the energy generation, the building was designed to conserve the energy it produced and consumed. Which is where Premier SIPS made a massive difference. The large, solid core panels, were factory manufactured and delivered to the jobsite. The offsite construction method not only made for fast installation (over older building framing methods) but its solid core nature created an extremely air tight and efficient envelope that conserved the solar energy generated.

Indoor Learning Environment

Improving the performance of the building envelope allows for smaller heating equipment to be specified—in this case an extremely efficient central air source heat pump. Each of the five learning “pods” that house the classrooms also contains a heat recovery ventilator (HRV) that provides mechanical ventilation, ensuring healthy indoor air quality and capturing heat from air that is exhausted from the building. Carbon dioxide sensors determine when mechanical ventilation is needed based on occupancy and how much natural ventilation is being provided through operable windows.

“In addition to daylighting, the other thing the windows in each classroom are doing is providing natural ventilation and cooling,” said Grant. “The district does not air condition schools so we designed as many operable windows as possible to meet a target of 10 percent of the floor area for cooling.”

Connecting with Energy and Ecology

At 355 kW, the photovoltaic installation on top of the Finn Hill Middle School is the largest on any school in the state. It provides 40 percent of the school’s electricity needs, and the building is designed with enough south-facing roof area to make the school net-zero-energy in the future.

The solar panels are split between each of the five pods. Each pod of classrooms is metered separately and the results are displayed on a touchscreen in the main gallery, allowing students to see differences in energy use and production.

Finn Hill is also unique in that it will manage 80 percent of its stormwater onsite through a series of rain gardens. Rainwater funnels off roofs and other hard surfaces through courtyard rain gardens where it will supply native plants. Through the windows in each classroom and the school’s environmental curriculum, students maintain a direct relationship with the outdoors and natural ecology.

Additional Sustainability Features:

- 47% more efficient than ENERGY STAR target

- Net Zero Energy ready design

- High Performance glazing

- Mechanical sun shading devices on windows

- 13 rain gardens treat 80% of site runoff

- Designing with SIPs and glulam beams reduced structure and thermal bridging through the building envelope.

The school has achieved many notable accolades including:

- 2012 SIPA Building Excellence Award

- King County Sustaining Green School - Level 4

Learn more about what makes Finn Hill green from the Architect here.

Ariel Construction Shot, Finn Hill Jr. High

The Lake Washington School District in suburban Seattle is building a new public school designed to be 47% more energy efficient than targets set under the U.S. Department of Energy’s EnergyStar® program.

The Finn Hill Junior High in Kirkland, Washington, uses Structural Insulated Panels (SIPs) from Premier Building Systems for a more airtight and well-insulated structure than typical school construction methods.

The school design by Mahlum Architects includes 6-inch-thick SIP walls and a 10-inch-thick SIP roof. The SIP panels arrive at the job site in large, ready-to-install sections, which helps reduce gaps and air leakage in the finished building. Continuous insulation throughout each panel’s height, depth, and width further protect against heat loss.

The SIP panels will help the school district reduce energy costs, and allow for smaller, more cost-effective mechanical systems. Reducing heating and cooling consumption was critical for the building’s “net-zero energy ready” design, meaning that the potential area for the roof-mounted solar panels is sufficient to power all the school’s needs. The school will open with one of the largest solar panel installations in the state.

“Every aspect of the design and construction must be considered in an integrated way when energy conservation goals are so ambitious,” says Anjali Grant, AIA, LEED AP, Project Architect. “Utilizing SIP panels not only supported the strategies for energy savings, it allowed for a smooth and rapid assembly process, shaving weeks off a tight construction schedule,” adds Mitch Kent, AIA, Project Manager with Mahlum.

The new Finn Hill Junior High is a single-story, approximately 120,000-square-foot building replacing an existing school located on the same site. It is designed to serve 600 students, plus 150 students in an “Environmental Adventure School” located within the building. The school will include space for core academic instruction, special education, fine arts, technology, physical education, library, and commons.

In collaboration with the design team, Mahlum Architects designed the school to an energy consumption target of 25 kBTU per square foot per year, compared to an EnergyStar™ Target Finder average energy use of 47.3 kBTU per square foot per year – a 47% improvement. By comparison, older schools in the Seattle area consume upwards of 88 kBTU per square foot per year, making the Finn Hill Junior High approximately 70% more energy efficient than older buildings.

The new Finn Hill Junior High complies with the Washington Sustainable Schools Protocol of the State Office of the Superintendent of Public Instruction.

Finn Hill Junior High Project Summary

- Location: Kirkland, Washington (Seattle area)

- Building size: 120,000 square feet (approx.)

- Structural Insulated Panel area (walls and roof): 200,000 square feet (approx.)

- Project status: Under construction

- Scheduled opening: Fall 2011

- Funding source: 2006 school district bond measure

- Design Team: Mahlum Architects, Seattle; Arup (Mechanical, Electrical, Plumbing, Telecom), Seattle; Cascade Design Collaborative (Landscape), Seattle; Coughlin Porter Lundeen (Civil, Structural), Seattle

- General Contractor: Babbit Neuman Construction, Steilacoom, Wash.

- SIP Manufacturer: Premier Building Systems, Fife, Wash.

Want to view more construction photos? See more here.

About Premier Building Systems

Premier Building Systems leads the construction industry in the research, development, and manufacturing of high-performance, energy-efficient structural insulated panels (SIPs) and related materials. The company is a leader in working with design professionals, contractors, and code officials on innovative SIPs applications. For more information about Premier’s products and services, contact us or visit our homepage.

About Mahlum Architects

Founded in 1938, Mahlum is a firm of 90 people with offices in Seattle, Washington, and Portland, Oregon. The firm is committed to creating enduring architecture that enriches the human experience. www.mahlum.com

About Babbit Neuman Construction

Babbit Neuman Construction Company was founded in 1999 by Scott Babbit and Rick Neuman. After twenty years in the commercial construction industry, they teamed their expertise with an outstanding group of individuals whose knowledge and integrity matched their own. The company’s expertise is with concrete and wood-framed projects, with a focus on commercial buildings and institutional work, including schools and security facilities.

Related Portfolio

Start The Project Conversation

High-performance buildings start with better systems.

Premier SIPS deliver a building envelope that outperforms traditional framing in efficiency, strength, and long-term durability. If your project demands higher performance and greater predictability, let’s talk.